|

Place of Origin: |

CHINA |

|

Brand Name: |

Edith |

|

Model Number: |

16,20,25,32,40 |

|

Minimum Order Quantity: |

Negotiable |

|

Price: |

Negotiable |

|

Packaging Details: |

Carton package/Wooden cases |

|

Delivery Time: |

Depending on the order quantity |

|

Payment Terms: |

L/C, T/T |

|

Supply Ability: |

Negotiable |

|

Disc diameter |

Customized Accepted |

Material: |

Alumium Alloy |

|

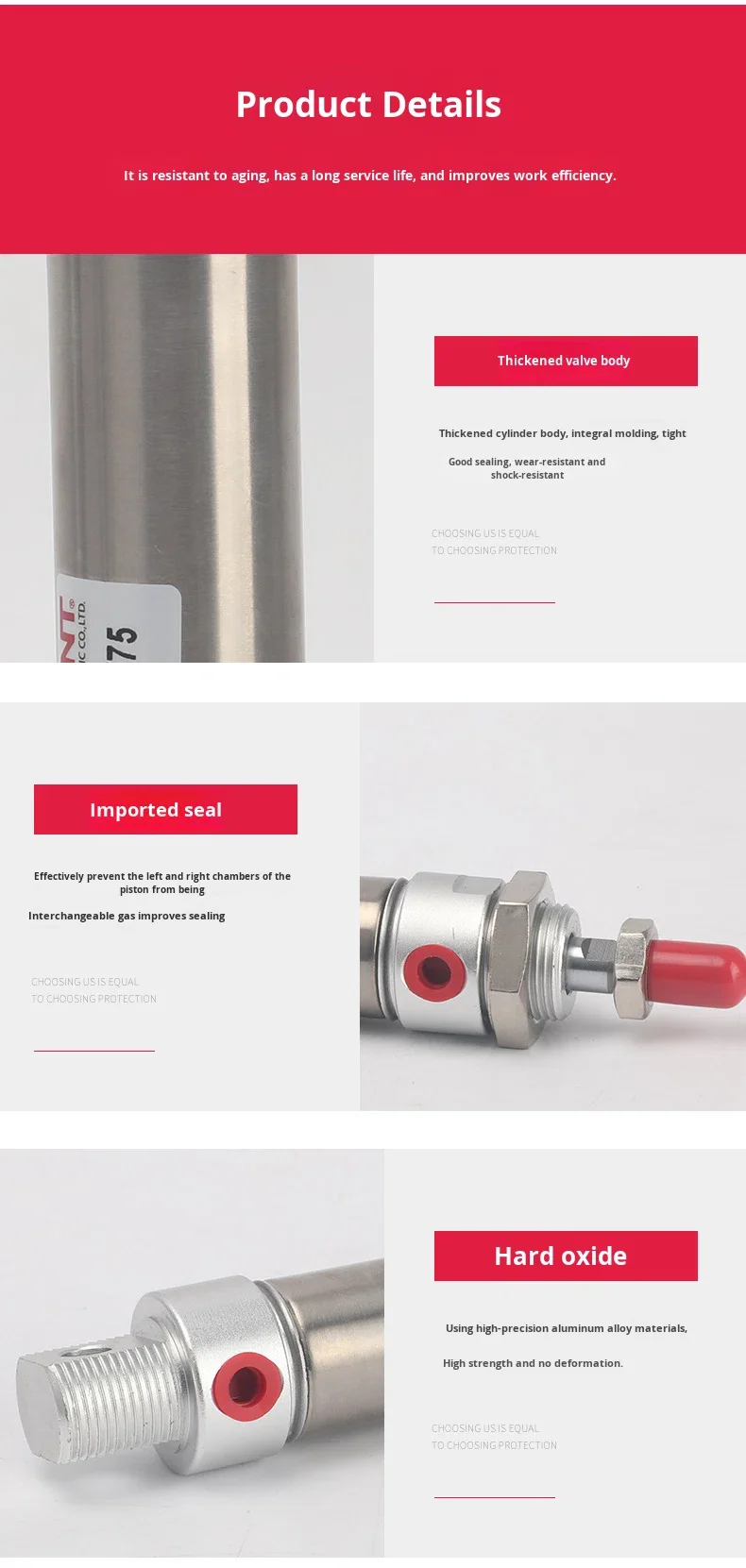

Highlight 1: |

Not easily deformed |

Highlight 2: |

Anti-Aging Insulated |

|

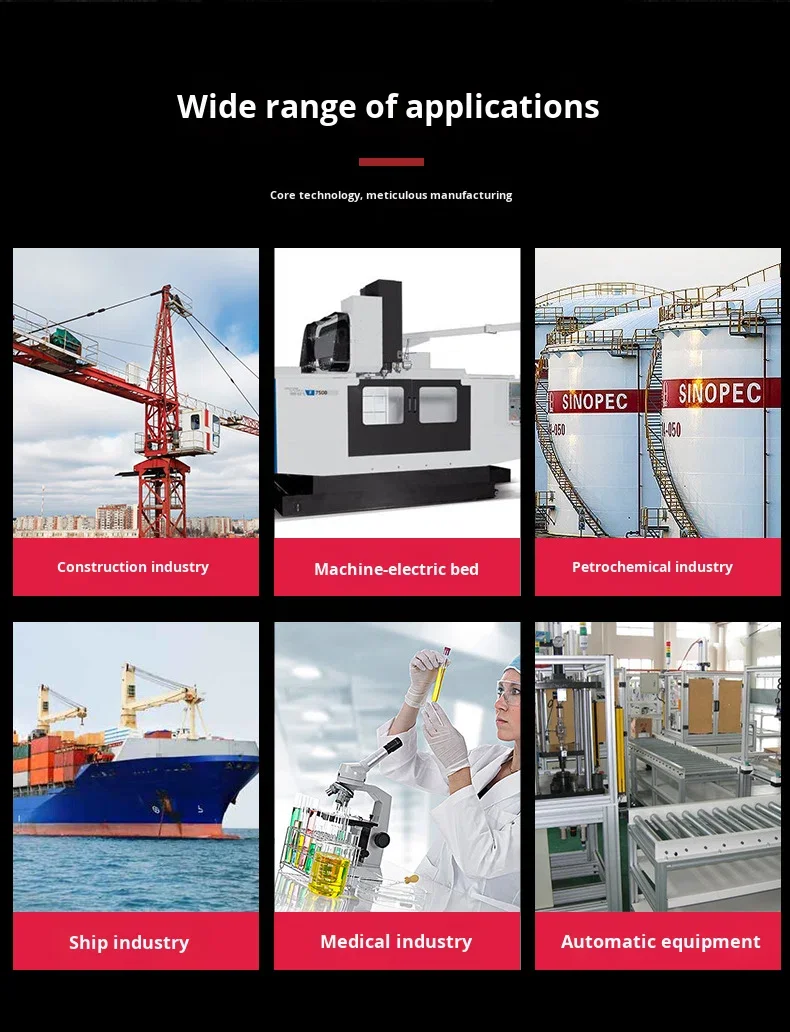

Application: |

Industry |

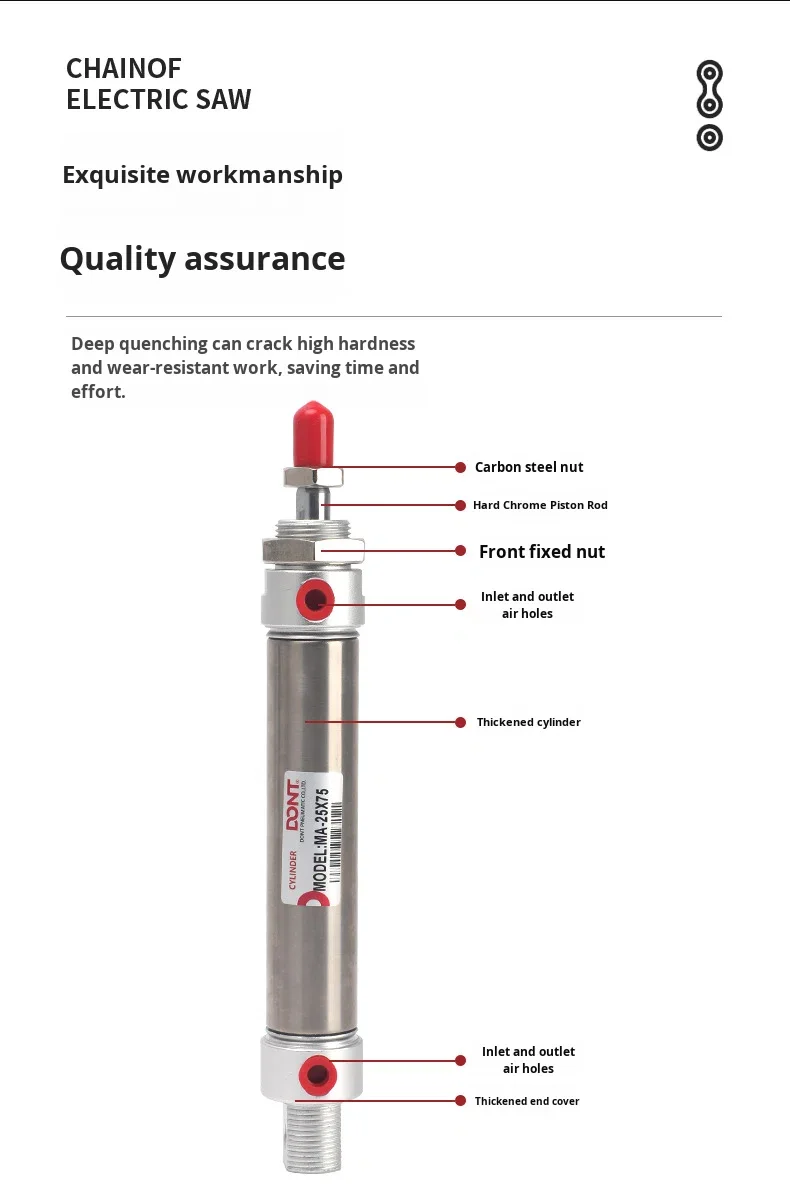

Name: |

MA Series Mini Cylinder |

|

High Light: |

High-Temperature Resistant |

||

Process Steps |

ODM |

ODM |

Step 1 |

CustomerRequirement |

CustomerRequirement

|

Step 2 |

SchemeAppraisal |

SchemeAppraisal

|

Step 3 |

ProfileConfirmation(Packing Dimension Functional)

|

Negotiation Cooperation

|

Step 4 |

Sample Design |

Quote

|

Step5 |

Small BatchProduction

|

Sample Confirmation

|

Step 6 |

Product Confirmation

|

Small Batch Production

|

Step7 |

- |

Product Confirmation |

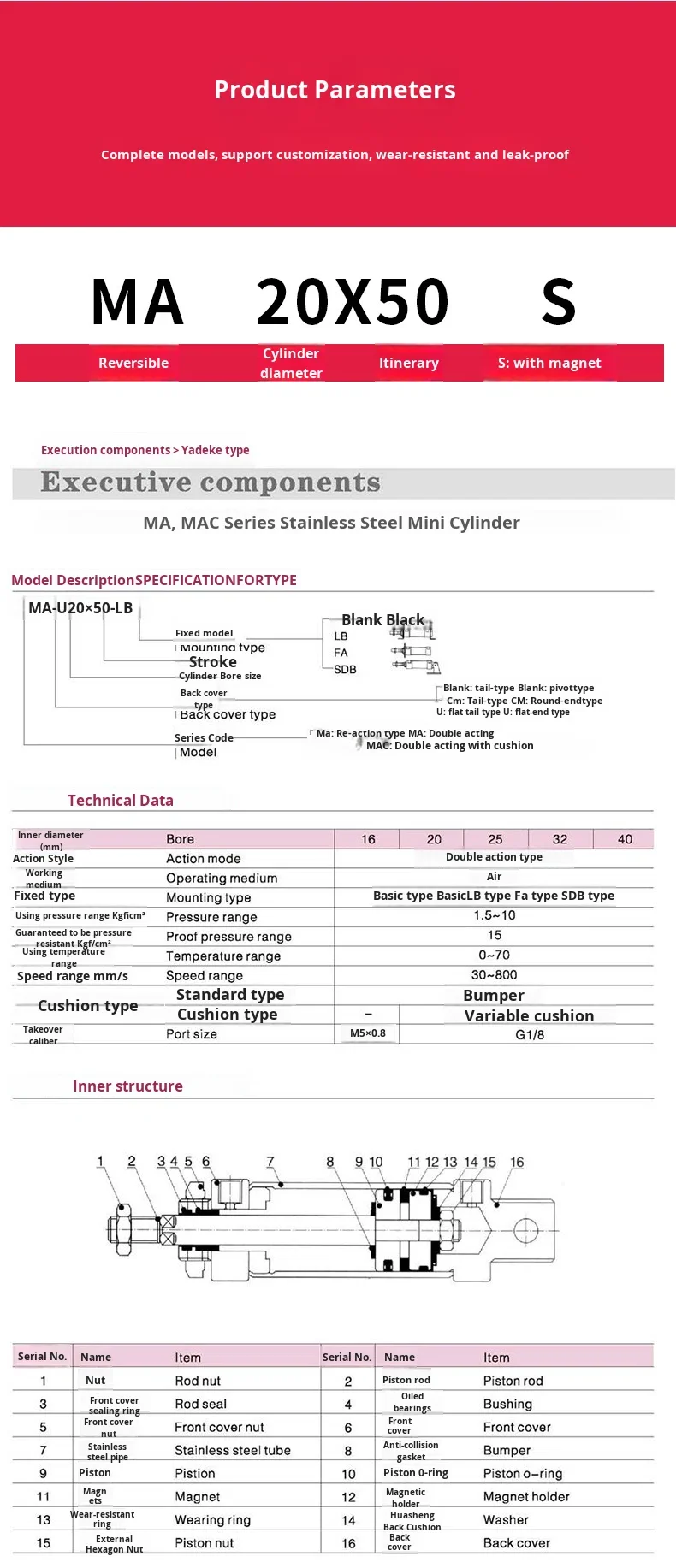

| Parameter Category | Description | Standard Range | Remarks |

|---|---|---|---|

| Bore Size (D) | Inner diameter of the cylinder barrel | Φ16, 20, 25, 32, 40, 50, 63 mm | Designed for varying thrust requirements, complying with universal industry specifications |

| Action Mode | Double-acting / Single-acting | Double-acting: MA/MAD/MAJ/MAC; Single-acting: MSA/MTA | MA is the basic double-acting model; MAC is equipped with adjustable cushioning |

| Stroke (S) | Effective piston travel distance | 10–500 mm (commonly used) | Standard stroke tolerance: +1.0 mm for ≤150 mm strokes; +1.4 mm for >150 mm strokes |

| Operating Pressure | Working pressure range | Double-acting: 0.1–1.0 MPa; Single-acting: 0.2–1.0 MPa | Guaranteed proof pressure: 1.5 MPa (test pressure) |

| Working Medium | Compatible gas type | Clean compressed air | Recommended filtration precision ≤5 μm; suitable for oil-free or micro-oil lubrication systems |

| Operating Temperature | Ambient and medium temperature | -20℃–70℃ | Low-temperature-resistant seals are required for sub-zero applications; maximum temperature limit is 70℃ |

| Speed Range | Piston operating speed | Double-acting: 30–800 mm/s; Single-acting: 50–800 mm/s | Recommended speed range: 30–500 mm/s for high-frequency operating conditions |

item |

value |

weight (kg) |

1 |

place of origin |

China |

structure |

Series Cylinder |

power |

Pneumatic |

body material |

Stainless Steel |

warranty |

1 Year |

standard or nonstandard |

Standard |

Mode of action |

Double action / single action |

Itinerary (S) |

10~500mm (Commonly Used) |

Use pressure |

0.1~1.0MPa for relapse type; 0.2~1.0MPa for single-acting type |

Working medium |

Clean compressed air |

Operating temperature |

-20℃~70℃ |

Speed range |

double-acting type 30~800mm/s; single-acting type 50~800mm/s |

Cylinder bore |

16,20,25,32,40(mm) |

Product name |

MA Series Mini Cylinder |

Material |

Alumium Alloy |

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy