Understanding Pneumatic Tees: What is a pneumatic tee? The pneumatic tee is a type of equipment that has proven useful in various machines and factories. It is one in a family of devices designed to move air from point A to B. This SIMEIERTE pneumatic pistons is because the term 'pneumatic' refers to working with air in order for these tools to be able make a machine function optimally. Below, we will help you understand what pneumatic tees are and how they work in vocational facilities or other places where machines dominate.

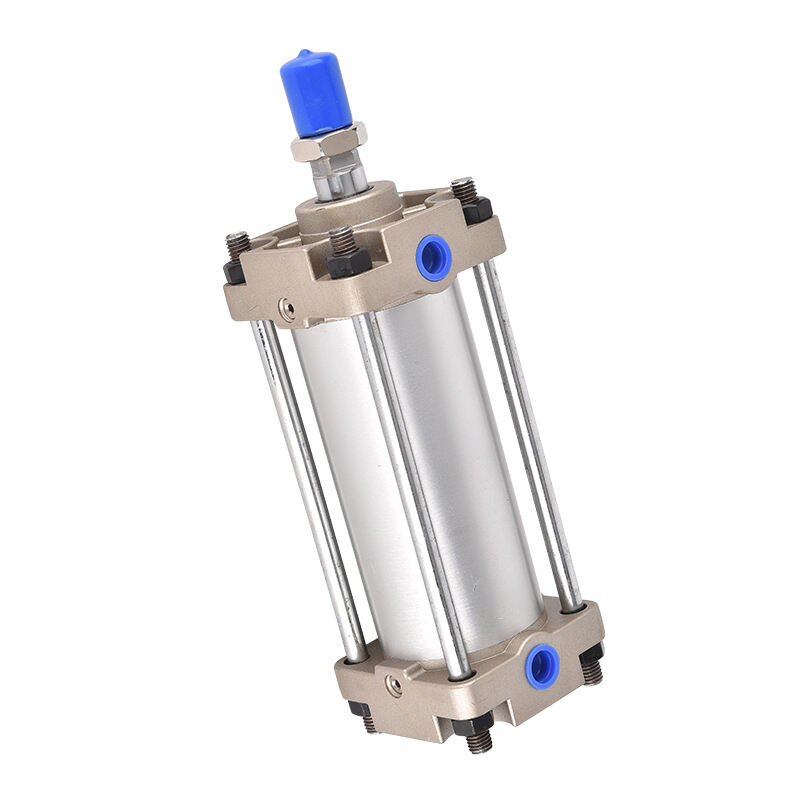

The pneumatic tee is a special piece that makes air can go in different ways but will not be blocked. This article has 3 holes and it is a small pipe. Key Features The design of this product is unique which means you can connect other tools just like the hoses and valves onto it easily, including all given main users process insights. The pneumatic tee hooks up to a pressurized air source (this could be your air compressor), and allows you to feed compressed air into multiple tools at one area. It makes things easier and gives you a lot more room. SIMEIERTE pneumatic connector is a little part in the tee that goes back and forth called as plunger. As you rotate the center green handle, this changes how parts of your tee adjust to allow air flow through these T-tubes in order to control where it goes and how much different tools would get.

You now know what is a pneumatic tee, so how to properly install one in your air system. Before anything, turn off the air supply and release any remaining pressure in your pneumatic hoses. Safety first - be sure to complete this part! Then look for the location of your tee. This is normally on the principle air line. Cut the main air line very carefully at that point. Make sure you cut a straight line, so your tee seals up all good once you connect supplies. If the cut is not higher than the spout, then when you drive by yourself, SIMEIERTE connector pneumatic will lead to air leaks later on. Install the tee and connectors on your newly cut line. Be sure to use sealant on every connection so as not the results are always present leakage. Reopen the air supply and listen/watch carefully for any leaks (a hissing sound).

Why should manufacturers utilize a pneumatic tee for your applications in the Industrial Process? A big reason is that one single air compressor can be connected to multiple machines at a time. You have also the advantage that it is energy-effective, reducing the need for multiple compressors which will be required extra space. Pneumatic tees are nice because it is a flexible system. By opening or closing any machine that you want, air flow is regulated. Where this can be really handy is when you have to move things around your plant. Since then, installation options with pneumatic tees are an easily executable process. That installation you could not believe it takes place allows that save time and money on repairs, to allow you portico concentrate in other work requisite activities.

Even the pneumatic tees can have problems sometimes as any other tool. In cases where just a little bit of air is needed, if the tee does not allow airflow to pass easily it might bring machinery and equipment to an unceremonious halt. This could slow down the production process. If this is the issue, you may have to take apart the tee and clean it (particularly where plunger goes in) - dirt or blockages here can greatly affect performance. System failures can also result in leaks. When you locate a leak, be sure to inspect all connections and check for tightness. The problem may require sealing or fresh connectors to remedy. Dirty air supply sometimes also bring problems so make sure your clean the damp from time to time as well.

Suzhou Edith Electric Co., Ltd. manufactures manipulator vacuum suctions cups, fixtures (suction cup seating) tools for Pneumatic tee, jigs as well as other automation-related accessories. The company's products are widely utilized by new energy, tunnels air, steel, glass, packaging, automotive electronics food, chemical, everyday printing, as well as many other industries. The company abides by the business principle of "technology first practical innovation, customer first, and customer service first", reflecting the value of warmth in service, while increasing customer satisfaction as the primary direction, and pursuing the best customer service.

Our products can be Pneumatic tee to meet the requirements of our customers, making us stand out from other brands. The product quality is higher, the reliability is better and it is able to meet the requirements of customers who are more demanding. The product provides comprehensive and thoughtful after-sales service. For customized products, customers are required to provide drawings or physical objects, and we'll provide a quotation that are based on these drawings or physical objects. Additionally, we will provide sample products for free, but do not have to pay for shipping charges. Once the deposit is paid, we will arrange the custom-made products and deliver them as quickly as we can. The time to deliver customized items is usually between 15-20 days, depending on the amount.

Suzhou Edith Electronics Co. Ltd. The company has a long background, and is stocked with the latest technological and Pneumatic tee. This allows it to be flexible to changing customer needs. Our company is dedicated to providing top-quality products, services, and research to help develop the industry's development of pneumatic parts. The company that makes vacuum cups is determined to offer customers the finest quality products. In addition, it increases pre-sales as well as after-sales services to increase customer satisfaction. Our company is always focused on the principle of "pursuing high-quality, giving first the most importance to service and using the latest technology".

We have a Pneumatic tee and business professionals to offer our customers comprehensive assistance and support, from consultation with the product to order processing, then to after-sales service. We can help customers pick the most suitable product with the help of a professional and a good customer relationship management.The company employs a group of designers and engineers modern offices, standardized workshops, and cutting-edge production technologies. It is a high-tech company that combines scientific research, production and development. The company is staffed by a team of experienced and highly-trained sales engineers and design engineers to provide more efficient solutions and services to customers.

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy