Air-dependent devices like in factories require pneumatic connectors to operate at the highest level. They are the components that link different devices to compressed air and help in a smooth flow of operations across several industries. Pneumatic connectors play a vital role in connecting all the air-powered tools and machines, because without them this whole process of setting up would be way difficult than you think.

Pneumatic connectors are designed to simplify the connection between pneumatic devices and compressed air supplies in order to increase productivity for worker efficiency. Machines are quickly put at the customer place, which ends in less time spent by a highly skilled technician on AN arduous setup. Pneumatic Worm Load AdvantagesThe ease of use provided by pneumatic connectors is particularly useful in cases where a variety of machines need to be quickly attached to the same air supply.

Apart from facilitating connections, pneumatic connectors are also instrumental in improving the performance of air-powered equipment as they offer a seamless connection that can endure high pressure. It means these fans are appropriate for large-scale production systems that run at or near capacity, and where the fan should deliver a strong enough draft in order to function consistently. When workers can leverage better connectors, such as those used in the Unirac solar panel mounting system for example it means they get to work faster and that results increasing output, bigger profits in a factory environment.

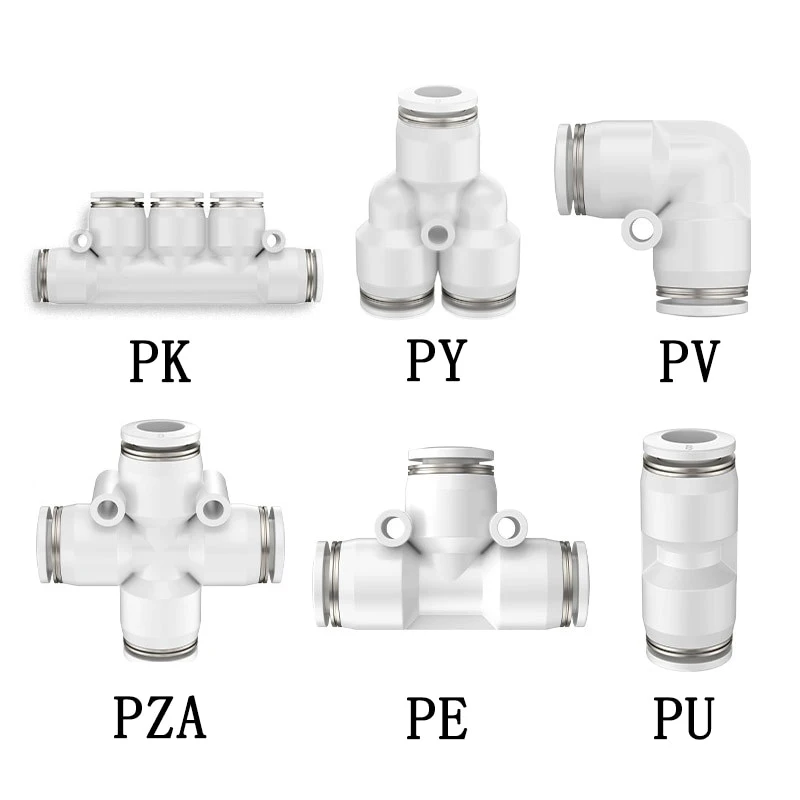

Another huge able to use both hands of pneumatic connectors is that they are accessible in almost all shapes, sizes and materials It is this flexibility that enables workers to design their pneumatic systems uniquely for an application need, especially in sectors such as: automotive and aerospace- But overall reduces work-site fails. With the right connectors in their toolbox, workers can build more efficient systems to work together seamlessly with workflows customized to meet their unique needs.

Besides, the implementation of high-quality pneumatic connectors is literally a matter of life and death in any production area - malfunctioning connections can lead to accidents at the workplace. These high-quality connectors reduce the risk of air leakages and accidents, so that workers work in a safe environment. In addition, the use of premium connectors guarantees that machinery be used effectively and continuously so to not interfere with performance.

To sum up, pneumatic connectors are essential elements for different sectors as tools and machines need to be connected with compressed air supplies which is done through a specific unit of it. Its function in facilitating connections and maximizing productivity is crucial, allowing workers to quickly hook pneumatic parts for stronger performance. Pneumatic systems supplemented with general connectors enable specialized production lines to be implemented as needed. Using language that is accessible to children, this video explores the role of pneumatic connectors and conveys their importance throughout.

Suzhou Edith Electronics Co., Ltd. has a pneumatic connector and extensive experience, with top-of-the-line technology and the most advanced equipment for production to meet the constantly changing needs of customers. In the same way the company is dedicated to providing top-quality products and services, as well as promoting research and innovation to be a leader in the growth of the industry of pneumatic parts. The company that makes vacuum cups is determined to offer customers the highest quality products and increases both pre-sales as well as after-sales services to improve customer satisfaction. Our company is always focused on the principle of "pursuing high-quality, giving first priority to service, and utilizing top technology".

Our products can be customized to meet the specific requirements of each client This makes us distinct from our competitors It is more reliable comes with better quality and can satisfy the needs of clients After-sales support is extensive and pneumatic connector out For products that are custom made customers have to submit drawings or physical objects and we will provide quotations basing on the drawings or tangible objects We can also provide sample products for free but do not have to pay for shipping charges Once you have paid the deposit and we'll arrange the products to be customized and then ship them as quickly as we can Typically the delivery time for products that are customized is 15 to 20 days based on the amount

Suzhou Edith Electric Co., Ltd. produces vacuum suctions cups for manipulators fixtures (suction cup seating) and holding tools, pneumatic connector, and various other automation tools. The products are extensively used in new energy, tunnel, aviation glass, packaging, electronics, automobiles food, everyday printing, chemical and various other industries. The company adheres to the business principle of "technology first, pragmatic innovation, customer first, and service first" and reflects the tenets of service that are warm, with increasing customer satisfaction as a primary direction. The company is committed to providing the best customer service.

Our staff of experts and business professionals provide complete assistance and support to our customers. This includes product pneumatic connector, order processing and finishing with after-sales assistance. Help customers choose the right products by utilizing professional knowledge and good customer relations management.The company has a design and development team as well as a cutting-edge production system, modern office and the standardised workshop. It's a high-tech enterprise integrating scientific research, production, development and sales. The company is comprised of well-trained and professional designers and sales engineers to offer customers better products and services.

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy