Ever heard of pneumatic fittings? These components form a large part of air systems. Air systems, as shown by the name itself helps machines and tools to work in a right manner. In this blog post, we will discuss how pneumatic fittings work and the best types of compression-style air brake fittings to use in your system depending on where you need a fitting for operation; some tipsTechniques to pick out which type would serve as an appropriate fitting for each kind of job, subtle variations among all kinds.

Pneumatic fittings are tiny but one of the essential components for connecting various parts in air systems. Compressed air needs to power your machinery and tools in air systems. It also means they have to be moving some air in order for them to work right. The fittings assist in encouraging the air to traverse the system as a whole. This makes it easy to plug and unplug resources when, as in your case you need some changes. This is most handy in cases of repairs and settings. Another important aspect of air leaks is that they lead to wasting energy and sometimes even perilous circumstances, pneumatic fittings enable stopping such waste at its source.

I mean when you really think about it, an air leak is exactly that...leaking the air where you do not want to and this will only decrease your machines effectiveness. Not only does this use up unnecessary energy it puts maltreatment on the tools which typically then perform less effectively. This is the reason why it becomes essential to have proper pneumatic fittings which add more value in making any air system safer and efficient.

Example 1: Quick connect fittings - as the name suggests, these types of fittings allow for parts to be connected and disconnected quickly. These kinds of ties are really good for places where you frequently need to change things, like when trying out different pieces of equipment. All those of us who have hosed in hand are ready and quick-connect fittings save a lot if time.

Compression fittings: In this system, the fitting has a compression ring that is compressed against the tubing as it fits into place-creating an almost bulletproof seal. This makes them ideal for high-pressure applications and they are commonly seen in hydraulic systems where the pressure is a critical factor. Compression Fittings - If you find yourself in the position of needing something that can handle a lot of pressure, compression fittings are frequently what is needed.

There are a few key things to consider when choosing the right pneumatic fitting. Before anything else, you need to determine the fitting's purpose Different fittings may be needed for different jobs. You also need to consider the air pressure and temperature that fitting will be exposed to, what size tubing you will use with it, and in what kind of an environment your system is going to be placed into. Experts are there to help you out, this is why seeking a piece of advice may save being stuck on the unsuitable fitting afterward. And by weighing these factors in your head while consulting with someone can finally lead you straight into suitable fittings for particular needs.

Pneumatic fittings have many different varieties and it's important to distinguish the differences between them. There are fittings that a several kind of work, and some fitting custom to fixtures. It could be as well that one kind of fitting is easier to use, handle more pressure (or less), if it goes hot or cold regularly and so on. Learn about these differences to make a more informed decision when choosing fittings for your air system.

Our professional team and business professionals provide complete support and pneumatic fittings to our customers. It starts with consulting on the product, processing of orders and finishing with after-sales support. Help customers decide on the most appropriate products by utilizing professional knowledge and effective customer relationship management.The company employs a group consisting of design engineers and developers, modern offices, standardized workshops, and cutting-edge production technology. It's a high-tech enterprise that integrates scientific research, development and production. The company is staffed by a team that is highly trained and professional sales engineers and design engineers to provide superior solutions and services to customers.

Suzhou Edith Electronics Co. Ltd. This company is a part of a rich history, and is equipped with the most modern technology as well as manufacturing equipment. This allows it to pneumatic fittings to the ever-changing needs of its customers. Our company is dedicated to providing high-quality products, services and research to help develop the industry's development of pneumatic components. The manufacturer of vacuum cups strives to provide customers with top quality products. The company enhances both pre-sales, and after-sales services to enhance customer satisfaction. Our company is always focused on the principle of "pursuing high-quality, giving first priority to service, and using the latest technology".

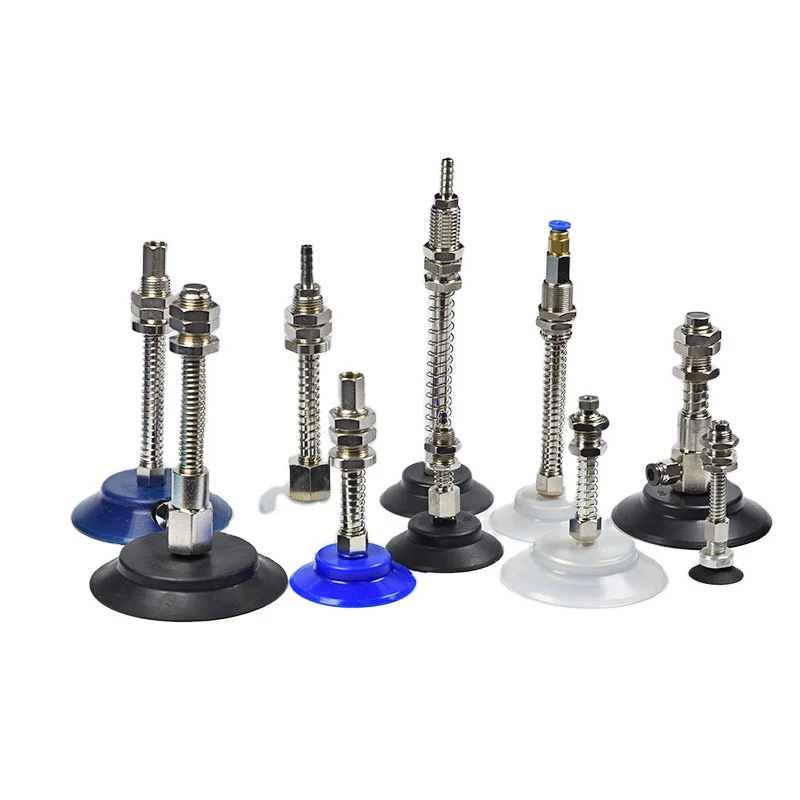

pneumatic fittings The company primarily produces vacuum suction cups for manipulators as well as fittings (suction cups seats), fixtures, holding tools, jigs, and other accessories for automation. The products are extensively used in tunnel, aviation glass, packaging, automobile, electronics food, everyday printing, chemical and various other industries. The company's business philosophy is "technology first, practical innovation, customer first and service first" which is a reflection of the concept of warmth in service. It is focused on improving the customer's satisfaction, and aims to deliver perfect customer service.

Our products can be customized to meet the specific requirements of each client This makes us distinct from our competitors It is more reliable comes with better quality and can satisfy the needs of clients After-sales support is extensive and pneumatic fittings out For products that are custom made customers have to submit drawings or physical objects and we will provide quotations basing on the drawings or tangible objects We can also provide sample products for free but do not have to pay for shipping charges Once you have paid the deposit and we'll arrange the products to be customized and then ship them as quickly as we can Typically the delivery time for products that are customized is 15 to 20 days based on the amount

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy