Do you seek a way to attach numerous air tools? In that case you might want to use something special, for instance a 1/2″ air fitting. Let's get into more detail on these handy connectors and find out how they work.

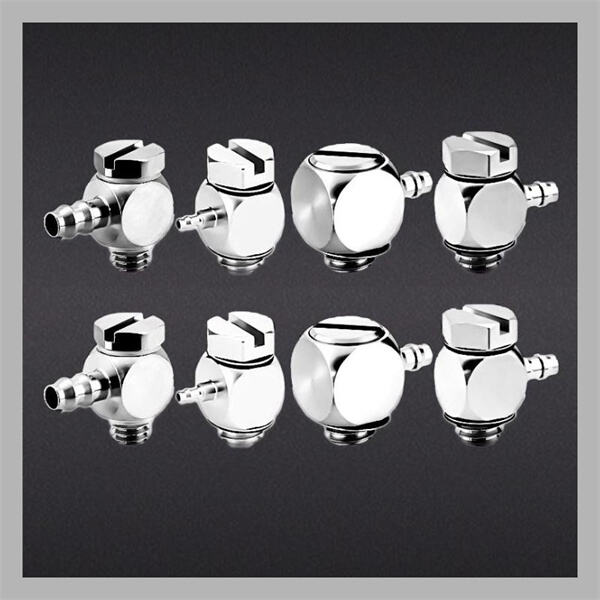

A 1/2 air fitting is a minute thing, but an extremely significant part of the systemfor connecting multiple parts of any air power operation. Those fittings normally have two ends. One end is connected to chat carries the air on a hose or pipe, while the other end connects with whichever tool you want and can be a spray gun, nailer gun etc. The 1/2 inch designation means that is how big the hole in the fitting is, where air will pass through. The way to pick the right size is as following, it needs to be the same diameter of your hose/pipe or it will not function properly.

There are a few things to consider when selecting a 1/2 inch air fitting. Step 1: Check the fitting is exactly your hose/pipe size. If it does not fit correctly air will leak, which is bad and squeezed. The second is to take a look at your air system pressures and temperatures. You must select the fittings that are required to suit your system pressure temperature. Then, think about how you want to interface with the fittings. There are also some that easily screw in place, whereas others only snap on and off which can save you time during tool changeovers or maintenance.

The main advantage of 1/2 inch air fittings is that they allow easy connection and disconnection between different sections of the air system. This allows you to easily change from one tool or make a quick repair without any problems. Furthermore, they enhance the performance of your air system for providing adequate airflow from start to end without any leakages. Allowing more fresh air to flow will, as a bonus help you save energy (and money!) in the long run – for both yourself and those extra CO2 points!

They are pretty simple to install an put a 1/2 inch air fitting in. On the very first note you have to take care that both end of your hose or pipe is trimmed well. The fitting is then screwed in affording a tight seal. Then, it is recommended to apply some lubricant onto the fitting before you bring it up in your hose or a pipe. This lube makes it easy to screw in and out the fitting later. When screwing the fitting into place, make sure that it is snug and will not fall off but do NOT overtighten as this may cause damage. If you want to keep your air fittings in top condition, then getting them checked for any signs of wear and tendency — bi-monthly or at least once every three months is recommended. If you notice any cracks or they appear to be worn, then it makes sense to just replace them. It's also a good habit to periodically grease those fittings.

Question 1 – Look for signs of wear (cracks, leaks etc.) Answer A If the hose fitting shows signs of wear, you should change it before something worse happens.

A. Properly functioning air fittings can save you energy and prevent leaks by keeping air flowing smoothly, which ultimately helps keeps costs low in the long run.

Suzhou Edith Electric Co., Ltd. manufactures manipulator vacuum suctions cups, fixtures (suction cup seating) tools for 1 2 inch air fitting, jigs as well as other automation-related accessories. The company's products are widely utilized by new energy, tunnels air, steel, glass, packaging, automotive electronics food, chemical, everyday printing, as well as many other industries. The company abides by the business principle of "technology first practical innovation, customer first, and customer service first", reflecting the value of warmth in service, while increasing customer satisfaction as the primary direction, and pursuing the best customer service.

We have a highly skilled team and business associates to provide customers with comprehensive support and services, from product consultation to ordering, and on to support after-sales. Professional knowledge and excellent customer relationship management, help customers to choose the right product and provide expert guidance.The company has an in-house design and development team as well as a cutting-edge production system, modern offices and a standardized workshop, and is an innovative high-tech company that 1 2 inch air fitting scientific research, production, development and sales. The company is comprised of well-trained and professional designers and sales engineers who can provide customers with more efficient services and solutions.

Suzhou Edith Electronics Co., Ltd. has a long-standing history and years of experience, backed by top technology and modern production equipment to meet the constantly changing demands of customers. Our company is dedicated to providing top-quality products, 1 2 inch air fitting, and research that helps develop the industry's development of pneumatic parts. To make their customers more satisfied The vacuum cup maker always strives to improve technology, offers customers top-quality products and enhances the pre-sales as well as after-sales support. Our mission is to "pursue excellence, and give priority to customer service and possess top technology".

Our products can be 1 2 inch air fitting to meet the requirements of our customers, making us stand out from other brands. The product quality is higher, the reliability is better and it is able to meet the requirements of customers who are more demanding. The product provides comprehensive and thoughtful after-sales service. For customized products, customers are required to provide drawings or physical objects, and we'll provide a quotation that are based on these drawings or physical objects. Additionally, we will provide sample products for free, but do not have to pay for shipping charges. Once the deposit is paid, we will arrange the custom-made products and deliver them as quickly as we can. The time to deliver customized items is usually between 15-20 days, depending on the amount.

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy