अपने मशीनों, रोबोटों और अन्य गेड़्जेट्स को चालू रखने के लिए कुशल तरीके की तलाश में हैं? यदि नहीं, तो आपको मिनी वायु सिलेंडर का प्रयोग जरूर करना चाहिए! यह सुंदर उपकरण गैस, वायु के यांत्रिक गुणों का उपयोग कर कINETic energy का उपयोग करता है, जिससे इसे वायु प्रवाह पर निर्भर करने वाले असंख्य प्रणालियों में उपयोग किया जा सकता है।

वायु सिलेंडर क्या है? वायु सिलेंडर छोटे ट्यूब होते हैं जो कम्प्रेस्ड वायु को उपयोग करके पिस्टन को आगे-पीछे खिसकते हैं। यह पुनरावर्ती गति बहुत ज़्यादा उपयोग की जाती है क्योंकि यह छोटे उपकरणों या वैल्वों को चलाने में मदद करती है, जबकि यह बड़ी मशीनों को भी चला सकती है। यह एक छोटे से इंजन की तरह है जो वायु का उपयोग ईंधन या बिजली के बजाय करता है।

तो क्या इन मिनी वायु सिलेंडर को विशेष बनाता है? पहले तो वे वास्तव में छोटे और हलके हैं। यानी, वे ऐसे छोटे हैंडल में घूम सकते हैं जो अन्यथा पहुँचने योग्य नहीं होते, बड़ी मशीनों की तुलना में बहुत आसानी से। यह बात भी है कि वे चालू होने के लिए संपीड़ित हवा पर निर्भर करते हैं, बिजली पर नहीं, जिससे उन्हें आम तौर पर अन्य शक्ति के स्रोतों की तुलना में अधिक विश्वसनीय और सस्ते माना जाता है। यह फायदा है क्योंकि इससे उन्हें विभिन्न पर्यावरणों में लागू किया जा सकता है बिना अतिरिक्त सामग्री की आवश्यकता हो।

उन्हें बहुत तेज़ और सटीक होने के लिए भी जाना जाता है, जो मेरे विचार में मिनी एयर सिलिंडर्स को एक उत्कृष्ट खरीददारी बनाता है। यह उन्हें तेज़ और सटीक रोबोट-आधारित सभी संयोजन लाइन कार्यों के लिए बहुत उपयोगी बनाता है। उदाहरण के लिए, एक तेज़ उत्पाद संयोजन लाइन में आपको कुछ ऐसा चाहिए जो तेजी से चल सके और प्रभावी रूप से काम करे। मिनी एयर सिलिंडर्स इसे बहुत ही प्रभावी रूप से करते हैं! वे बहुत ही संचालनीय हैं। साधारण स्विच का उपयोग उन्हें चालू या बंद करने के लिए किया जा सकता है, जबकि अधिक उन्नत नियंत्रण आपको यह तय करने में मदद करते हैं कि वे कितना बल, गति या स्थिति प्रदान करते हैं।

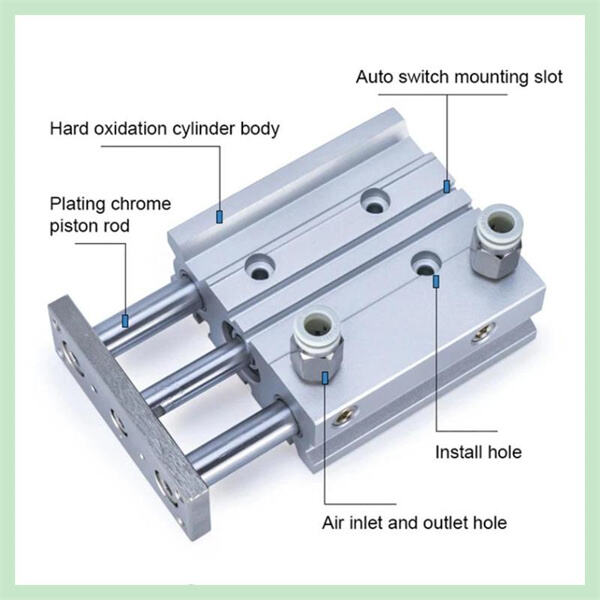

इसलिए आपको शायद यह सोचने लगा हो कि ये मिनी एयर सिलिंडर्स ठीक तरीके से कैसे काम करते हैं। इस घटक में एक ट्यूब सिलिंडर के लिए होता है, अंदर एक पिस्टन होता है और हवा का प्रवाह के लिए एक इनलेट और आउटलेट होता है। संपीड़ित हवा को इन खोलों में से एक में भरा जाता है, जहाँ यह पिस्टन को अपनी लम्बाई के साथ स्लाइड करने के लिए मजबूर करता है। आप इस गति का उपयोग विभिन्न कार्यों, उठाने या धकेलने के लिए कर सकते हैं।

एयर सिलेंडर की शक्ति पर निर्भर कुछ विशिष्ट चीजें होती हैं। ये पिस्टन का आकार, दबाव और संपीड़ित हवा की सीमा हो सकती है और पिस्टन को कितना दूर जाने की क्षमता है। इस मोटर घर्षण यह भी कहता है कि, इन चर चरणों में कुछ संशोधन के साथ आप विभिन्न कार्यों के लिए बेहतर काम कर सकते हैं। यदि आपके पास उदाहरण के लिए बड़ा पिस्टन है या अधिक हवा का दबाव है, तो यह इस मिशन में काम कर सकता है। इस प्रकार ऑप्टिकल स्व-समाप्ति गुण, छोटे आकार के एयर चैम्बर के लिए अनुप्रयोग विशेष रूप से व्यापक है।

अगर आप अपने प्रणाली की दक्षता में सुधार करना चाहते हैं और स्थान, वजन, मूल्य बचाना चाहते हैं तो मिनी एयर सिलेंडर आपके लिए एक बुद्धिमान विकल्प है। क्योंकि उनका निर्माण काफी छोटा होता है, वे विभिन्न प्रकार की सेटिंग्स में फिट हो सकते हैं। उनके अनुप्रयोग विभिन्न उद्योगों में होते हैं, रोबोटिक्स के निर्माण और अनुप्रयोग सहित।

हमारे विशेषज्ञों और व्यावसायिक पेशेवरों की टीम हमारे ग्राहकों को पूर्ण सहायता और समर्थन प्रदान करती है। इसमें उत्पाद मिनी एयर सिलेंडर, आदेश प्रसंस्करण तथा बिक्री-उपरांत सहायता के साथ समाप्ति शामिल है। ग्राहकों को सही उत्पादों का चयन करने में सहायता के लिए व्यावसायिक ज्ञान और अच्छे ग्राहक संबंध प्रबंधन का उपयोग करें। कंपनी के पास डिज़ाइन और विकास टीम के साथ-साथ उन्नत उत्पादन प्रणाली, आधुनिक कार्यालय और मानकीकृत कार्यशाला है। यह एक उच्च-प्रौद्योगिकी उद्यम है जो वैज्ञानिक अनुसंधान, उत्पादन, विकास और बिक्री को एकीकृत करता है। कंपनी में अच्छी तरह से प्रशिक्षित और पेशेवर डिज़ाइनरों तथा बिक्री इंजीनियरों की टीम है, जो ग्राहकों को बेहतर उत्पादों और सेवाएँ प्रदान करती है।

हम अपने उत्पादों को प्रत्येक ग्राहक की आवश्यकताओं के अनुसार अनुकूलित करने में सक्षम हैं। यह हमें हमारे प्रतिस्पर्धियों से अलग करता है। यह एक और अधिक संक्षिप्त वायु सिलेंडर है, जो उच्च गुणवत्ता प्रदान करता है और ग्राहकों की आवश्यकताओं को पूरा कर सकता है। यह एक पूर्ण और कुशल बिक्री-उपरांत सेवा प्रदान करता है। अनुकूलित उत्पादों का आदेश देने के लिए, ग्राहकों को आरेख या भौतिक वस्तुएँ प्रस्तुत करनी होंगी, और हम चित्रों या भौतिक वस्तुओं के आधार पर उद्धरण प्रदान करेंगे। हम नि:शुल्क नमूने भी प्रदान करते हैं, लेकिन आपको फ्रेट के लिए कोई शुल्क नहीं लगाया जाएगा। जमा राशि के भुगतान के बाद, हम अनुकूलित उत्पादों की व्यवस्था करेंगे और उन्हें जल्द से जल्द भेज देंगे। अनुकूलित वस्तुओं के लिए डिलीवरी समय सामान्यतः मात्रा के आधार पर 15 से 30 दिनों के बीच होता है।

सूज़ौ एडिथ इलेक्ट्रिक कंपनी लिमिटेड। यह कंपनी मुख्य रूप से मैनिपुलेटर्स के लिए वैक्यूम सक्शन कप और फिटिंग्स (सक्शन कप सीट्स), फिक्सचर्स, होल्डिंग टूल्स, जिग्स तथा स्वचालन उपकरणों का उत्पादन करती है। इसके उत्पाद टनल, मिनी एयर सिलेंडर, स्टील ग्लास, पैकेजिंग, ऑटोमोबाइल, इलेक्ट्रॉनिक्स, फूड, डेली प्रिंटिंग, केमिकल और अन्य उद्योगों में व्यापक रूप से उपयोग किए जाते हैं। कंपनी "प्रौद्योगिकी को प्राथमिकता देना और व्यावहारिक नवाचार, ग्राहक को प्राथमिकता देना और सेवा को प्राथमिकता देना" के व्यापार दर्शन का पालन करती है, जो गर्मजोशी भरी सेवा के सिद्धांतों को दर्शाता है, जिसकी प्राथमिक दिशा ग्राहक संतुष्टि में वृद्धि करना है तथा श्रेष्ठतम ग्राहक सेवा प्राप्त करने का लक्ष्य रखती है।

मिनी एयर सिलेंडर की एक लंबी परंपरा और विशाल अनुभव है, दुनिया की शीर्ष प्रौद्योगिकी और उत्पादन के लिए सबसे उन्नत उपकरणों के साथ हमारे ग्राहकों की लगातार बदलती आवश्यकताओं को पूरा करने के लिए। हम उच्च गुणवत्ता वाले सामान और सेवाएं प्रदान करने के लिए समर्पित हैं, साथ ही नवाचार और अनुसंधान करने के लिए प्रेरित हैं ताकि प्रेरक घटक उद्योग के विकास का नेतृत्व किया जा सके। कंपनी जो वैक्यूम कप बनाती है, ग्राहकों को शीर्ष गुणवत्ता वाले उत्पाद प्रदान करेगी। कंपनी ग्राहक संतुष्टि में सुधार के लिए प्री-सेल्स के साथ-साथ आफ्टर-सेल्स सेवाओं में वृद्धि कर रही है। हम हमेशा "उच्च गुणवत्ता का पीछा करने, ग्राहक सेवा को सर्वोच्च प्राथमिकता देने और उत्कृष्ट प्रौद्योगिकी रखने" के लक्ष्य का पीछा करते हैं।

कॉपीराइट © सूज़हू एडिथ इलेक्ट्रॉनिक्स को., लिमिटेड. सभी अधिकार सुरक्षित - गोपनीयता नीति