Ram cylinders are some of the most essential components found in many devices and tools used daily. These surfaces help in the production of force which can be used to move heavy objects or other such jobs. Ram cylinders can operate from a variety of power sources, including air or special fluids. The most common such cylinder is the pneumatic ram, a type of pneumatic actuator that pushes linear through air.

As Pneumatic ram cylinders have numerous advantages, they are majorly used in a number of applications. Well, to begin with they are hassle free and easy to clean. This is a great advantage as they do not require heavy maintenance like some other types of cylinders. This great feature is saving businesses so much money and time, with less to fix up regularly, they last for longer.

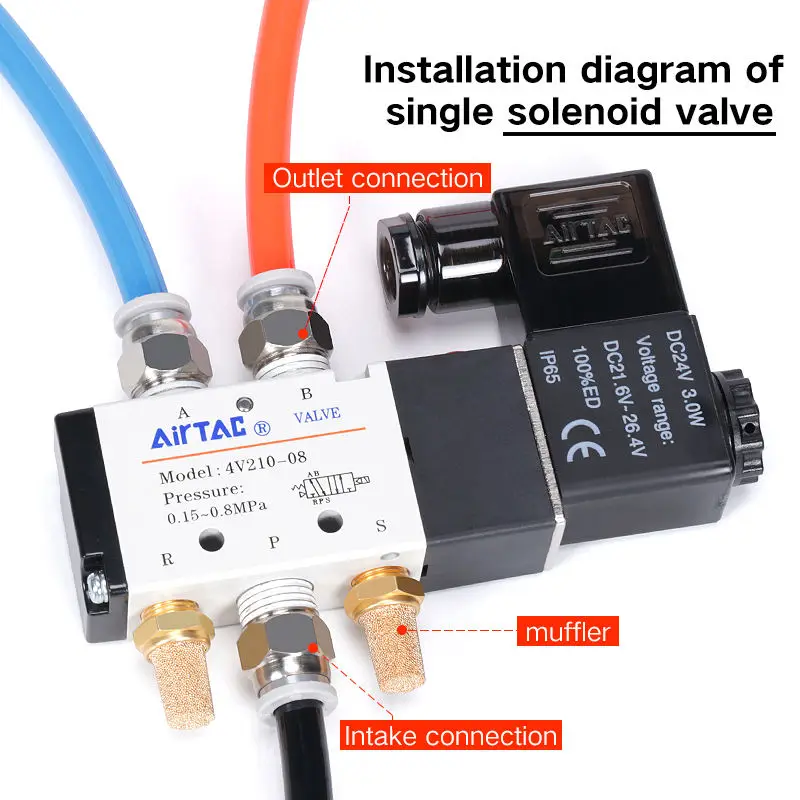

Pneumatic ram cylinders use compressed air to generate the force required for its movement. The compressed air is stored in a reservoir or special tank. As the cylinder has to course, it releases air into a valve system. Critical, because this valve system is the primary means by which air flows in and out of the cylinder, thus regulating how that particular piston behaves.

Compressed air creates force on the piston of a cylinder inside it. A rod connects a piston, moving the object to which it is attached with movement from the cylinder. And we can control which way the rod moves by controlling how much force is put on one side of it - in other words, what pressure level the compressed air going into our cylinder hose. Being able to control movement this way makes pneumatic ram cylinders valuable and versatile for many applications.

Ram cylinders are quite versatile and can be used for any number of tasks. You can use these to carry or move heavier stuffs, compress material, bend metal and are often used widely to crush things as well. Cylinders can be used in variety of processes and applications across manufacturing, automotive, construction or agri sectors. They are versatile tools that is essential in almost every element of life and industry.

One reason rams are so versatile is because they come in many sizes and shapes. Since they can be adapted to work in many different machines and tools this variety makes them versatile. Furthermore, you can make ram cylinders to give various amounts of power so that it may use for any kind of task like a simple lift or some difficult operation[].

This time, look at the size/shape of the cylinder. The important thing is to opt for the appropriate size and shape of cylinder from http://www.growsll.com/product/spring-return-cylinder.html that will fulfill duty requirements within a machine or tool. A cylinder may not work as well if it is uncomfortable. You also need to choose a cylinder that is capable of delivering the required amount of force suitable for your application.

Suzhou Edith Electric Co., Ltd. produces pneumatic ram cylinder with manipulator, fixtures (suction cup seating), holding tools, jigs, and other automation equipment. Its products are widely used in new energy, tunnel, aviation, steel, glass, packaging, automobile, electronics and food processing, as well as daily printing, chemical and other industries. The company's policy of business is "technology first, practical innovation, customers first, and first-class service" as a reflection on the principle of service that is warmth. The company's focus is on improving the satisfaction of customers, while also pursuing perfect customer service.

Suzhou Edith Electronics Co., Ltd. has a long-standing history and years of experience, backed by top technology and modern production equipment to meet the constantly changing demands of customers. Our company is dedicated to providing top-quality products, pneumatic ram cylinder, and research that helps develop the industry's development of pneumatic parts. To make their customers more satisfied The vacuum cup maker always strives to improve technology, offers customers top-quality products and enhances the pre-sales as well as after-sales support. Our mission is to "pursue excellence, and give priority to customer service and possess top technology".

We can customize our products to meet the specific requirements of each client This makes us distinct from our competitors The product's quality is superior reliability is better and it is able to meet the pneumatic ram cylinder of customers with higher quality The product is able to provide comprehensive and thoughtful after-sales service To order custom products clients must submit drawings or physical objects and we'll send quotations from the images or physical objects We can also provide sample products for free but you are not required to pay for shipping charges We will ship the customized items once we receive the deposit Typically the delivery time for customized products is 15-20 days depending on the amount

Our professional team and business professionals provide complete support and services for our customers. This includes the consultation of our products, through order processing and finishing with after-sales assistance. Through professional knowledge and excellent customer relationship management, help customers select the most appropriate product and offer professional advice.The company employs a group of designers and engineers, pneumatic ram cylinder, standardized workshops, as well as advanced production techniques. It's a high tech enterprise that combines scientific research, development, and production. The company employs a team of professional and well-trained design engineers and sales engineering to provide superior solutions and services to customers.

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy