Double acting pneumatics are unique for machines used in many different sets of applications across multiple industries. In factories and construction areas we can see many heavy machines are working which is powered by these special systems. In this article. we are going to tell you what double acting pneumatics is, why it makes a sensible choice for many applications and where do use them in our day-to-day lives.

The double acting pneumatics are mainly used to enable the machines work in numerous industries. These unique cylinders are used for lifting, pushing, pulling and moving parts of machines. The force that creates these movements is the centrifugal compression of air. Once this air is released, it generates pressure which moves the actions necessary for full functioning of the machines.

Double Acting Pneumatics are mostly associated with machines that do work in one way or another: Cranes move heavy things, presses perform material shaping operations stamping processes create parts; conveyor belts shuffle items from point A to place B. These machines have to be able to move quite heavy things both safely and powerfully, and double acting pneumatics gives them the reliable power source that they need in order for them to do what it is that there designed too.

There are many benefits of double acting pneumatic cylinders which make them the best choice for industrial use. They are relatively inexpensive to buy and maintain, making them an economically sound choice for businesses. The second one is, they are maintenance free; that means the workers do not have to spend a lot of time fixing or fueling them. And, finally, they are extremely reliable so that you rely on them to perform properly day in and day out for years.

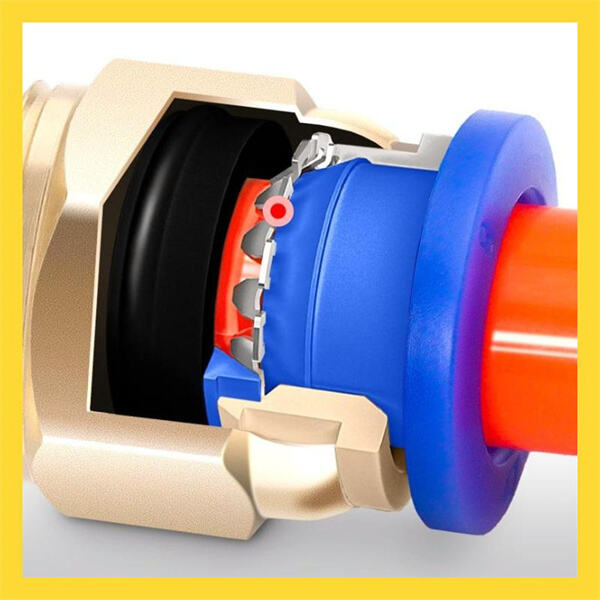

Exposed: LA Camilli CylindersCM7The exciting thing about cylinders like this is that they can both push and pull—without any external parts. They are very versatile devices, capable of doing both things and hence have become useful for many different tasks and applications. They find application in almost all types of machinery due to their versatile nature, thus saving time and money for industries.

These systems, are more than just pistons at the pumps they need valves to dictate airflow as well. As they serve as the point of on-off, these valves are important to have whenever we want our machines moving and resting. Also assist with the air moulding which will dictate in which way machines are going to move. An operator manage them tightly, to control the direction and flow of air ensuring smooth functioning of machinery.

Heavy-duty applications need such machines which are strong and at the same time reliable in nature. Double acting pneumatics are anything but this, with an application in the double acting area requiring an output twice that of the previous. They are able to perform exceptionally well even against the most extreme conditions ranging from extremely high pressure or temperature. They are known for their durability in challenging environments which is why they are chosen by many industries over others.

Our products can be customized to meet the demands of each client that is what sets us apart from other companies. The double acting pneumatic of the product is better, the quality is greater and it is able to meet the needs of clients with greater demands. The product offers a comprehensive and thoughtful after-sales service. For customized products, customers must submit sketches or physical objects and we'll give you a quote that are based on these drawings or actual objects. We can also provide free samples. However, you won't be charged for shipping. After paying the deposit and arranging the customized products and ship the items as soon as it is possible. Typically, the delivery time for customized products is 15-20 days, depending on the quantity.

Our staff of experts and double acting pneumatic provide complete support and services for our clients, beginning with advice on products, processing orders and finishing with after-sales service. Professional knowledge and excellent customer relationship management, we assist customers choose the most suitable product and provide expert guidance.The enterprise has a team of designers and developers as well as a cutting-edge production system, modern office and the standardised workshop. It's an advanced company that integrates research and development, production and sales. The company is staffed by a team of experienced and highly-trained sales engineers and design engineers to provide superior solutions and support to customers.

double acting pneumatic has a long tradition and vast experience, with world-class technology and the most advanced equipment for production to meet the ever-changing requirements of our customers. At the same time we are dedicated to delivering high-quality goods and services, as well as innovating and conducting research to lead the development of the pneumatic component industry. The company that makes vacuum cups will provide customers with top quality products. The company increases both pre-sales as well as after-sales services to enhance customer satisfaction. We always pursue the goal of "pursuing high-quality, giving first the highest priority to customer service and having excellent technology".

Suzhou Edith Electric Co., Ltd. The company primarily produces vacuum suction cups for manipulators and fittings (suction cups seats), fixtures, holding tools, jigs and automation tools. Its products are widely used in tunnel, double acting pneumatic, steel glass, packaging automobile, electronics food, daily printing, chemical and other industries. The company adheres to the business philosophy of "technology first and pragmatic innovation, with the customer first and service first", reflecting the tenets of service that are warm, with increasing customer satisfaction as its primary direction, and pursuing the best customer service.

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy