Pneumatic air fittings are an essential part of many jobs. And they help get compressed air from one place to the other, and that makes machines work better. In this writing, you are going to find out what pneumatic air connect does, what types can be found, which one you should choose, the possible problem you may encounter and the positive things when you apply it for your works.

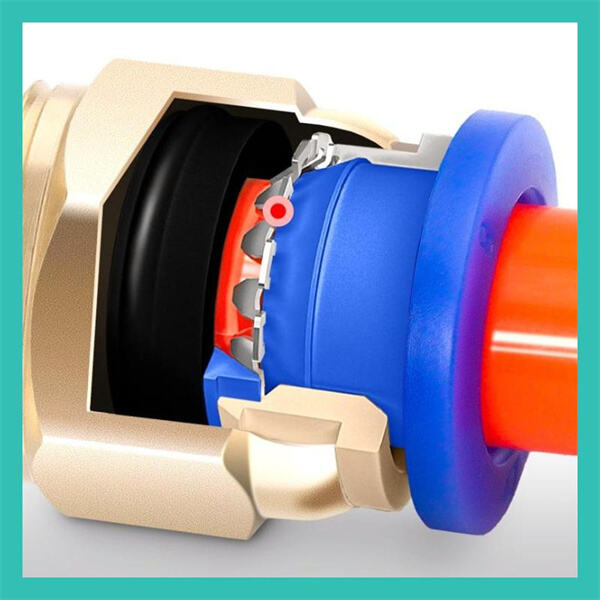

An pneumatic connector is a connector that joins one or more components in a system that use air to operate. Compressed air is thereby permitted to pass therebetween. These typically are composed of strong materials, such as metal or plastic, so that they can easily withstand a lot of pressure and use. They function by creating a perfect fit between the pieces, so air can move through without leaks.

Pneumatic air connectors come in a variety of types, all designed for specific work. A few popular kinds are quick-connect fitting, push-to-connect fitting, barb fitting, and compression fitting. Quick-connect fittings are always easy to install and provide for quick setups and breakdowns. Push-to-connect fittings require no additional tools. There are bumps on the tube which grip the tubing securely. Compression fittings must be tightened to seal.

When selecting a push-in air fitting, consider the type of tubing you plan to use, the size of the tubing, the size of the threads, the type of connection, how much pressure it will need to handle, and what materials blend with each other. Of course, it’s very crucial that you also take the producer of the connectors from a well known manufacturer as SIMEIERTE, just to ensure they’re of a good level of quality. Put the balls together and take care of them as per the manufacturer’s apps other-wise you may run into problems.

Although they are robust, pneumatic air connectors can experience issues, including leaks, clogs, or breakages with wear and tear. If you do find a leak, visually inspect the connections for damaged or exposed parts of broken seals and replace them as necessary. Try using compressed air or a cleaning solution to clean the connectors and tubing when you encounter clogs. If there is visible damage, replace the damaged components to prevent further problems.

Pneumatic air connectors have many benefits in the work, such as working well, installing easily, and useful in many applications. They enable fast and easy connection of parts and effectively reduce downtime and increase productivity. They are compatible with various equipment and can use in rugged conditions which suits many industries including manufacturing, automotive and construction. In general, pneumatic air fittings are tools that are an indispensable part of keeping the work flow operating well and remaining efficient.

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy