Think of a pneumatic cylinder as an adult helping you suck out the last bits from your cup. A straw can be used to push air out of the end that we blow into, which then moves items. That is the way pneumatic cylinders function, but using air as our breath while pushing and moving objects around through pressure of air.

The large pneumatic cylinders are ued in many ascpets to move some hevay things like big rocks, heavy machines and building materials. These cylinders can then do a variety of things to move the stuff, from pushing it back and forth or lifting up/down. They operate by compressing air, which is compressed into a reservoir and then transmitted through tubes to the cylinder. The compressed air fills up the top half of a cylinder and pushes down on a rod that is connected to whatever you need moved. This is how they lift things up and move even the heaviest items.

Pneumatic cylinders are employed in various areas and industries. In construction that could be handy, simply because they can carry these large instruments and hoist huge chunks of metal up to the place it belongs. In factories, it can be a giant pneumatic cylinder to move parts between machines or lift very heavy objects which are too weighty for workers. These cylinders are used all the way through to transport a cylinder within it not possible for any other than heavy vehicle by using in logistics industry which may help to put logistic goods from HS & down speed of large trucks or ships so that load and unload become faster. Pneumatic cylinders are also used to increase and…

Finally, pneumatic cylinders can be very strong and so one of the main reasons for using large bore ones is that they have enormous power once projected out. They are able to pick up and hold heavy things that a person cannot lift alone, which gives them value. This type of machinery is super accurate making it possible to put things in the exact right place every time without any errors. Moreover, pneumatic cylinders are constructed to be very robust that is why they can service over a long period whether the operation of them weeks in harsh environments.

Air pressure pushes the rod in large pneumatic cylinders. The air goes in a tank that can be reserved for some specific function and the pipe work is run to the cylinder. If you enter air into the cylinder, it will push the rod to go outside. The rod is connected to the object that needs to be lifted, such as a heavy item or piece of equipment. As the rod moves, it in turn carries along with itself that thing which has been attached to it. The rod goes back to its original state once the air pressure is relieved then such a cycle can be repeated again. This design is highly efficient in helping you move heavier objects with less effort from your end.

So, Safran said that it is important to know how can be safely use of large pneumatic cylinders. Keep a few key things in mind. Of course, the first thing you have to do is choose the right size cylinder for your job. If the cylinder is too small, you might not have enough to move even so close an object. Conversely, if the cylinder is too large and moves things around more quickly than what should be or not accurate enough it creates a problem. Second, we must treat the cylinder with caution and periodically check for leaks, clean it up well or replace worn out parts to maintain its performance. Lastly, one must follow safety precautions. This includes training everyone who will be using the equipment on how to safely operate it, wearing safety gear as needed (such as gloves or goggles), and ensuring that you regularly check over all of your lifting equipment for damage.

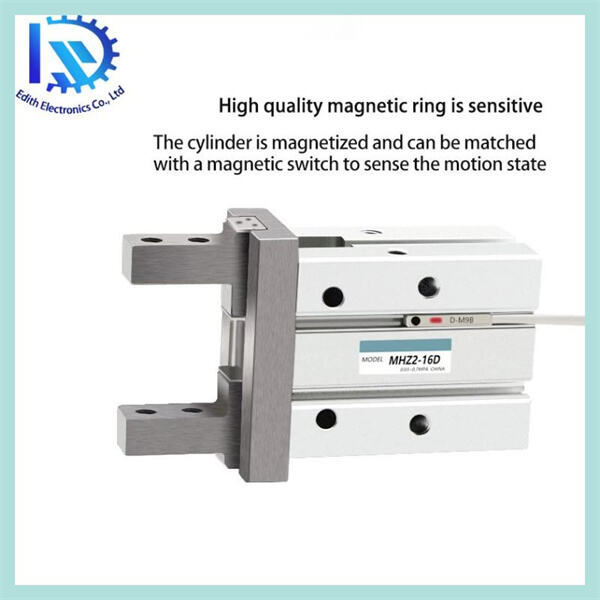

Suzhou Edith Electric Co., Ltd. produces vacuum suctions cups for manipulators fixtures (suction cup seating) and holding tools, large pneumatic cylinder, and various other automation tools. The products are extensively used in new energy, tunnel, aviation glass, packaging, electronics, automobiles food, everyday printing, chemical and various other industries. The company adheres to the business principle of "technology first, pragmatic innovation, customer first, and service first" and reflects the tenets of service that are warm, with increasing customer satisfaction as a primary direction. The company is committed to providing the best customer service.

We have a highly skilled team and business associates to provide customers with comprehensive support and services, from product consultation to ordering, and on to support after-sales. Professional knowledge and excellent customer relationship management, help customers to choose the right product and provide expert guidance.The company has an in-house design and development team as well as a cutting-edge production system, modern offices and a standardized workshop, and is an innovative high-tech company that large pneumatic cylinder scientific research, production, development and sales. The company is comprised of well-trained and professional designers and sales engineers who can provide customers with more efficient services and solutions.

We can customize our products to meet the requirements of each client This makes us distinct from our competitors. The product's quality is better, quality is large pneumatic cylinder, and it can meet the needs of clients with greater demands. It provides a complete and efficient after-sales support. To order custom products, clients must submit sketches or physical objects and we'll give you a quote from the images or actual objects. We can also provide free samples, but you will not be charged for freight. We will send the customized products as soon as we receive the payment. The time to deliver customized items generally takes between 15 and 30 days based on quantities.

Suzhou Edith Electronics Co. Ltd. The company has a long background, and is stocked with the latest technological and large pneumatic cylinder. This allows it to be flexible to changing customer needs. Our company is dedicated to providing top-quality products, services, and research to help develop the industry's development of pneumatic parts. The company that makes vacuum cups is determined to offer customers the finest quality products. In addition, it increases pre-sales as well as after-sales services to increase customer satisfaction. Our company is always focused on the principle of "pursuing high-quality, giving first the most importance to service and using the latest technology".

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy