| Process Steps |

ODM |

OEM |

| Step 1 |

CustomerRequirement |

CustomerRequirement |

| Step 2 |

SchemeAppraisal |

SchemeAppraisal |

| Step 3 |

ProfileConfirmation(Packing Dimension Functional) |

Negotiation Cooperation |

| Step 4 |

Sample Design |

Quote |

| Step 5 |

Small BatchProduction |

Sample Confirmation |

| Step 6 |

Product Confirmation

|

Small Batch Production |

| Step 7 |

|

Product Confirmation |

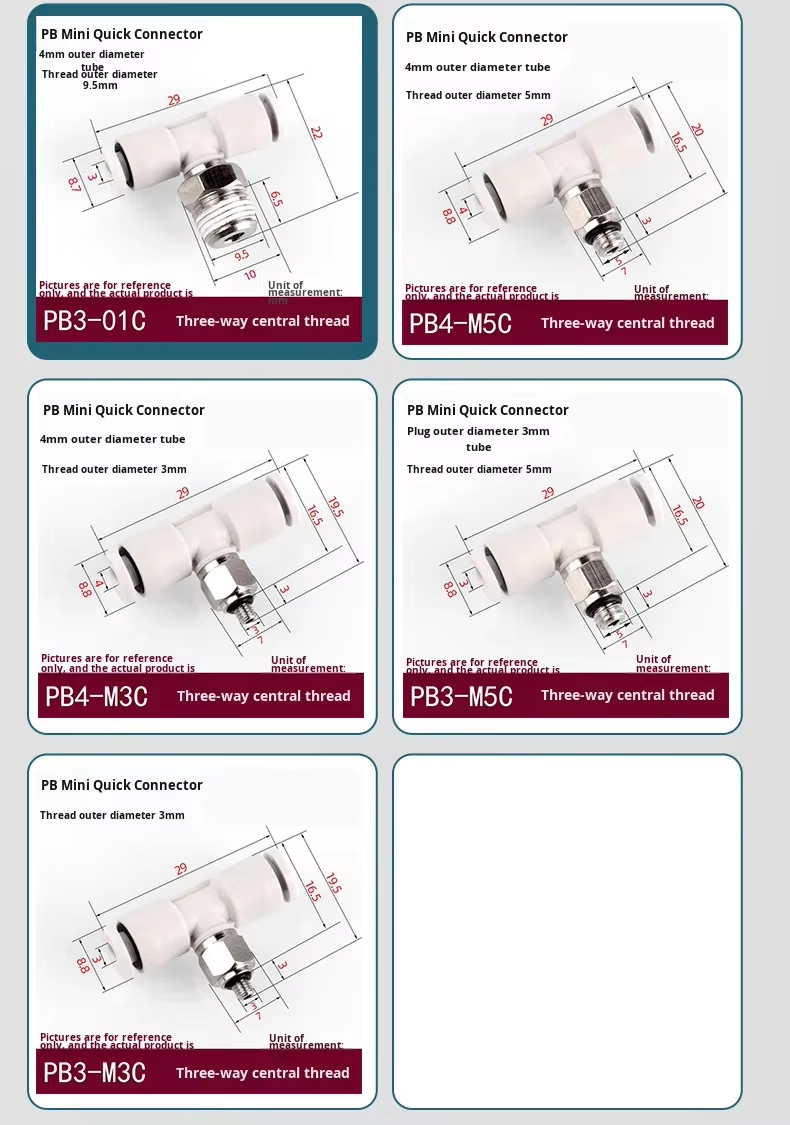

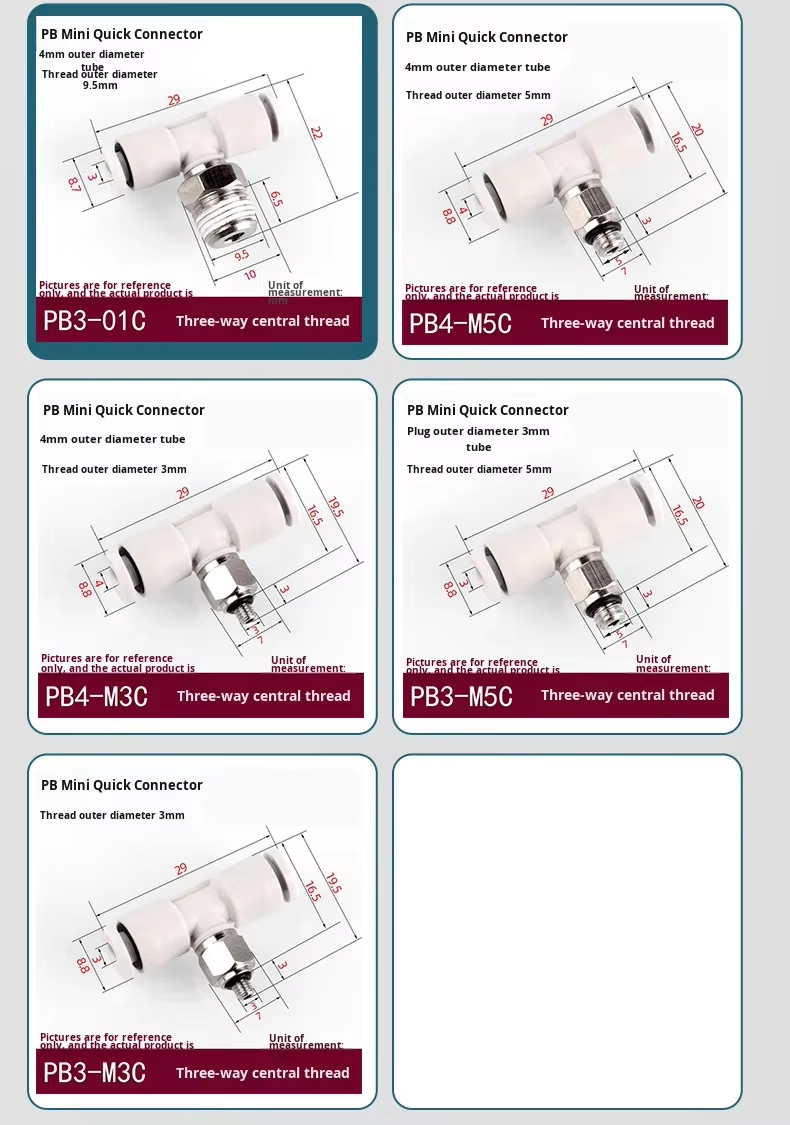

PB Series Straight Tee Micro Fittings

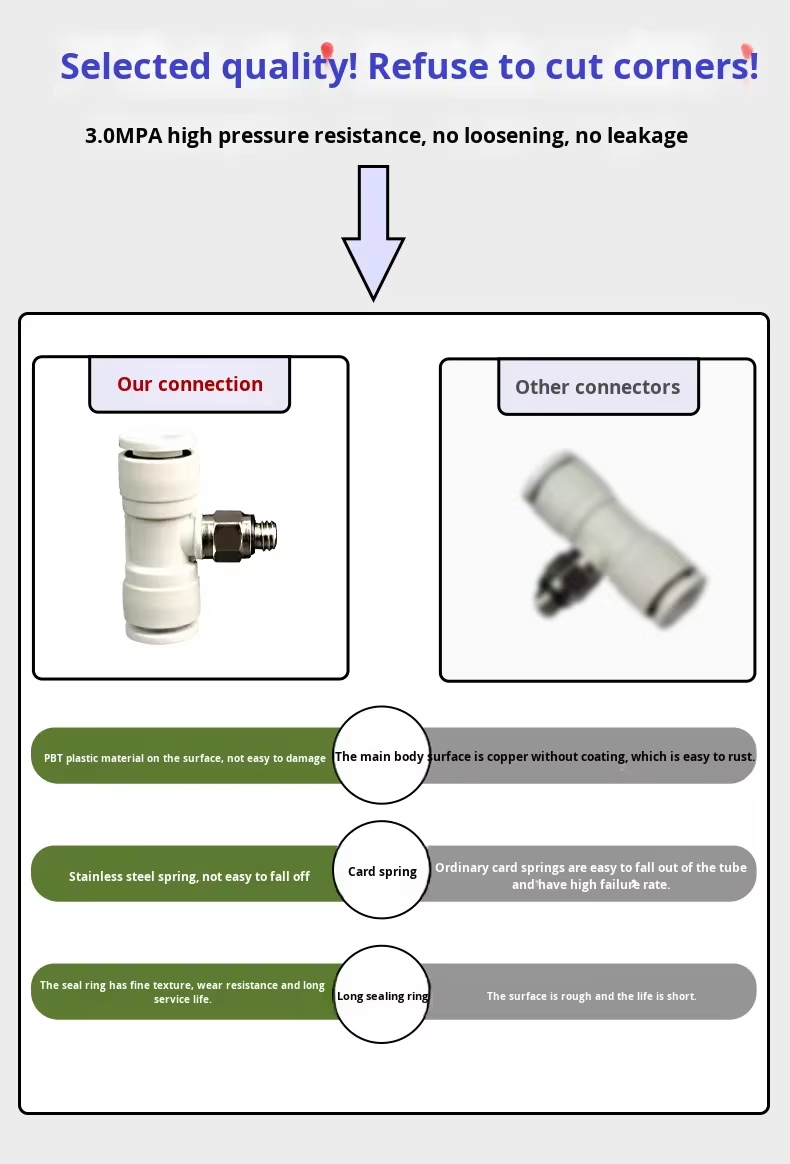

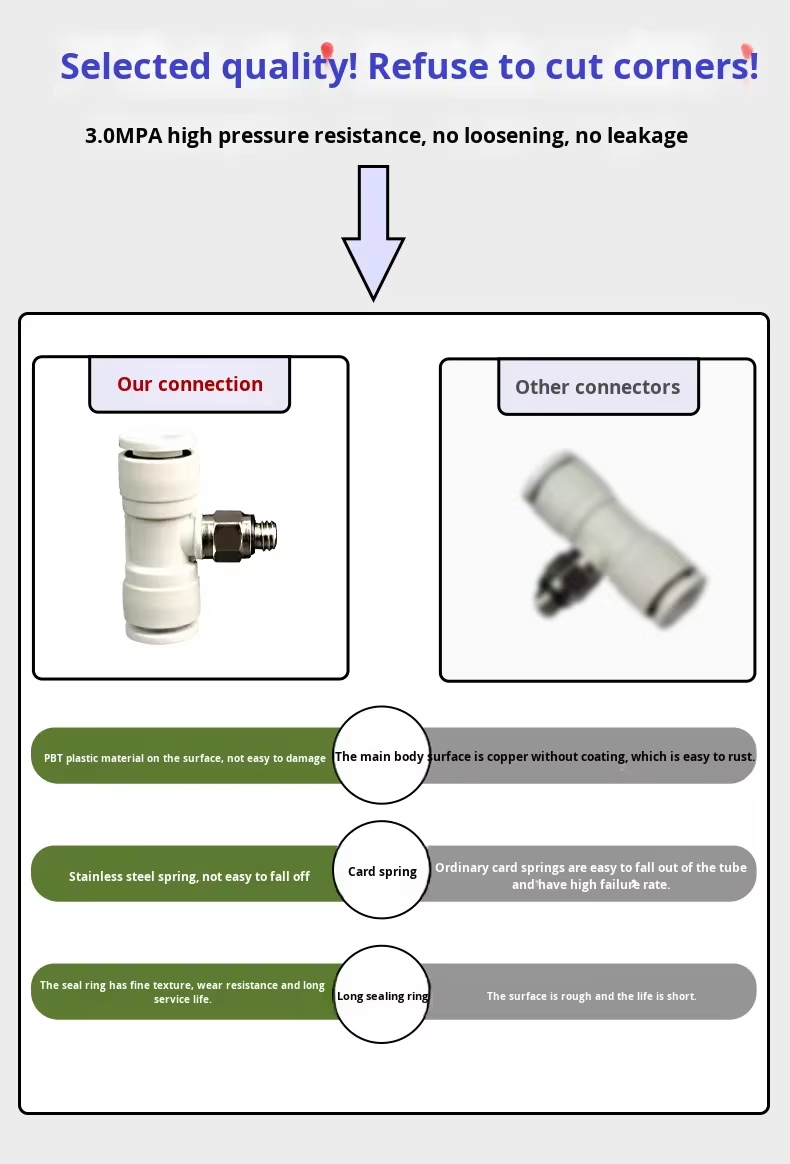

PB series straight tee micro fittings are mostly T-shaped push-in pneumatic fittings, commonly made of materials such as nickel-plated brass and PBT. They are suitable for pneumatic and hydraulic systems and play a core role in pipeline connection and fluid distribution in industrial scenarios. Below is a detailed introduction to their specific functions, core parameters, and application scenarios:

Core Functions

Pipeline Flow Distribution and ConfluenceWith its T-shaped structure, the fitting can either split a single path of fluid (such as compressed air or water) into two paths for delivery, meeting the air/water supply needs of multiple actuators; it can also merge two paths of fluid into one for transmission, adapting to the fluid deployment requirements of different pipeline layouts and ensuring the flexibility of fluid delivery.

Quick Assembly and Disassembly ConnectionAdopting a push-in design, it allows manual insertion or removal of polyurethane and nylon air hoses without additional tools, enabling efficient installation and disassembly and significantly reducing the time cost of pipeline assembly and maintenance. Moreover, the fitting can rotate 360° freely, allowing flexible adjustment of pipeline direction after installation and adapting to pipeline routing needs in confined spaces.

Sealing and Leak PreventionThe threaded parts are usually coated with sealant, and some models are also equipped with sealing gaskets. Meanwhile, it is matched with locking clips and sealing components, which can not only firmly clamp the air hose to prevent falling off but also avoid fluid leakage, ensuring the stable operation of pneumatic and hydraulic systems, and is suitable for sealing needs of fluid delivery from low pressure to normal pressure.

Correct Installation and Maintenance Methods for PB Series Straight Tee Micro Fittings

As core pipeline connectors for industrial pneumatic/hydraulic systems, the standardized installation and timely maintenance of PB series straight tee micro fittings directly affect the operational stability of the system. Below is a step-by-step installation process and key maintenance points:

I. Correct Installation Steps

Pre-installation Preparation

Accessory InspectionConfirm that the fitting model matches the applicable air hose specifications (e.g., PB4 is compatible with 4mm air hoses) and threaded interfaces (such as M5/R1/8). Check that the fitting’s seals (sealing rings, gaskets) are intact, the sealant on the threaded parts is uniform and free of defects, and the locking clips are free from deformation or loosening.

Pipeline PreprocessingUse a dedicated pipe cutter to cut polyurethane/nylon air hoses into flat, perpendicular ends, avoiding beveled cuts or burrs. Purge the interior of the pipelines with compressed air to remove dust, debris, and other impurities, preventing them from entering the fitting and causing seal failure.

Working Condition ConfirmationEnsure the installation environment is free of high temperatures (exceeding the 0–60℃ range) and strong corrosive media to prevent premature aging of the fitting materials.

Specific Installation Operations

Air Hose InsertionHold the air hose and align it with the push-in port of the fitting, then insert it vertically with force until the locking clip makes a "click" locking sound. Gently pull the air hose to confirm it is securely clamped, preventing air leakage due to incomplete insertion.

Threaded End ConnectionAlign the threaded end of the fitting with the equipment interface and tighten it evenly with a torque wrench according to the manufacturer’s specified torque (generally 1–2N·m for small-size threads). Never over-tighten, as this may cause thread slipping or fitting cracking. If the fitting is not pre-coated with sealant, wrap 1–2 turns of Teflon tape around the threaded part (note that Teflon tape must not enter the interior of the pipeline).

Pipeline Direction AdjustmentUtilize the fitting’s 360° rotation feature to adjust the branch pipelines to a reasonable layout, avoiding bending or twisting of the air hoses and ensuring smooth fluid transmission.

| item |

value |

| type |

Fittings |

| weight (kg) |

1 |

| machinery test report |

Provided |

| warranty |

1 Year |

| place of origin |

Jiangsu, China |

| Proof pressure |

1.5Mpa |

| Temperature range |

-5~60℃ |

| Color |

White |

| Customized support |

OEM |