Want to learn how large machines operate? Do you ever wonder how factories are able to churn out large numbers of products at such a fast rate? Industrial air cylinders are the answer to all these questions! To make factories work more effectively and faster, you need these special tools. In this post, we will take a look at what industrial air cylinders are used for and the different types of air cylinders available before exploring how they assist factories as well as what to consider when selecting them along with reasons why you should work with such companies that understand their stuff.

Factories have great need of industrial air cylinders as this are applied in so many ways to promote the products they manufacture. They use air to move things instead, which means that they assist in directing or influencing many machines. Such as shutting a door of machine in factory, we can use air cylinder to do this job. It is also used in transferring heavy machinery and separating individual products on an assembly line. If there were no air cylinders, factories would not operate as fast and effectively,possibly leading to longer waits for products. Because of this, air cylinders are integral parts in the process to help factories keep up with demand and ensure everything is running as smooth.

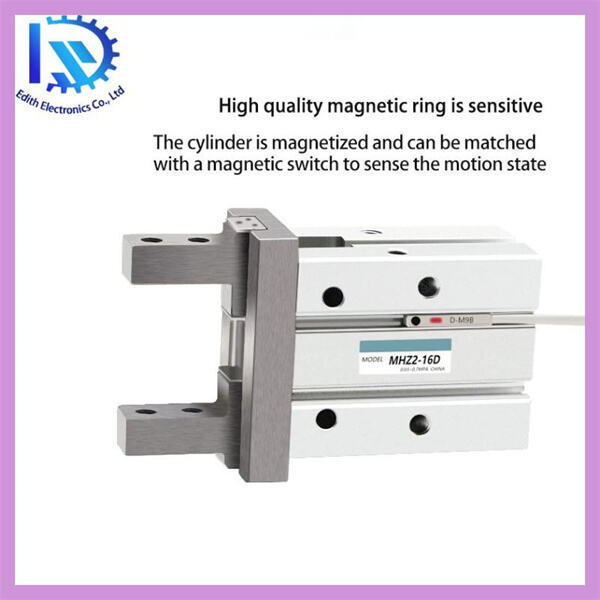

Industrial air cylinders come in all sorts of shapes and sizes to do anything you need done. Types of Air Cylinders — The two main types are single-acting and double-acting cylinders. Single-acting cylinders Single-acting units are driven by air pressure to move the piston in one direction only. In contrast, double-acting cylinders can use air to both push and pull the piston in equally two directions allowing them more versatility. Different sizes and shapes of air cylinders are available to perform different jobs in a factory.

Basically, you should know the properties of the air cylinder that is going to be selected or picked. Specifications are information that describes how powerful the cylinder is, what air pressure it can withstand and its weight. It aids you to think whether a particular air cylinder is suitable according to your factory requirements or not. By understanding these specifics, you can locate the best air cylinder for performing your desired tasks.

For a great number of reasons, reliable air cylinder technology is instrumental in helping improve the way factories function. Air cylinders can also be used to pick up or move heavy items, which would normally require a large number of people. Not only does this keep the workers safe from harm, but it also frees up time for them to do other things and allows us to get more work out of them. And better, and lighter actuators can do a job faster than people could ever hope to achieve — which helps the factory to turn out more products in less time.

Reliable air cylinder technology also helps factories avoid downtime. When it comes to machinery, downtime is the time that machines are not working because they have broken or need maintenance. In general, by keeping up with maintenance and properly caring for air cylinders they can work a very long time without any failure. That results in lower costs for repair — an essential factor for optimal production.

There are several important factors to consider when choosing air cylinders for factories. You must consider the bore (size) of the cylinder, its stroke length and how much pressure it is rated to handle before failing. You also have to consider where the cylinder is going. If it is subjected to a hard or harsh environment, say full of dust and chemicals you had better choose one specifically designed for the purpose if not your phone will soon pack up.

Our staff of experts and industrial air cylinders provide complete support and services for our clients, beginning with advice on products, processing orders and finishing with after-sales service. Professional knowledge and excellent customer relationship management, we assist customers choose the most suitable product and provide expert guidance.The enterprise has a team of designers and developers as well as a cutting-edge production system, modern office and the standardised workshop. It's an advanced company that integrates research and development, production and sales. The company is staffed by a team of experienced and highly-trained sales engineers and design engineers to provide superior solutions and support to customers.

Suzhou Edith Electronics Co., Ltd. This company is a part of a rich tradition, and is outfitted with the most modern technology and manufacturing equipment. This allows it to be flexible to the changing needs of customers. Our company is dedicated to providing top-quality products, services and research that helps develop the industry's development of pneumatic components. The vacuum cup manufacturer will provide customers with the finest quality products. In addition, it increases both pre-sales as well as after-sales services in order to increase satisfaction of customers. Our mission is to " industrial air cylinders excellence, and give priority to service, and use top technology".

Suzhou Edith Electric Co., Ltd. The company primarily produces vacuum suction cups for manipulators and fittings (suction cups seats), fixtures, holding tools, jigs and automation tools. Its products are widely used in tunnel, industrial air cylinders, steel glass, packaging automobile, electronics food, daily printing, chemical and other industries. The company adheres to the business philosophy of "technology first and pragmatic innovation, with the customer first and service first", reflecting the tenets of service that are warm, with increasing customer satisfaction as its primary direction, and pursuing the best customer service.

We can customize our products to meet the specific requirements of every customer and that makes us stand out from our competitors It is more reliable has an improved quality and is able to satisfy the needs of clients industrial air cylinders after sales is thorough and thoughtful For products that are custom made customers need to supply sketches or physical objects and we will provide quotations that are based on these drawings or physical objects Additionally we will provide sample products for free but do not have to pay for freight We will deliver the personalized items as soon as we receive the deposit The time of delivery for custom items is typically between 15 and 20 days based on the size

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy