The core function of custom-shaped special rubber rings is to meet the sealing, shock absorption, buffering and protection needs of non-standard equipment or special working conditions, make up for the structural and performance gaps that standard rubber rings cannot fill, and are widely used in industrial fields such as machinery manufacturing, automotive, chemical industry, and pneumatic-hydraulic systems. The specific functions are divided into the following categories:

Precise Sealing to Prevent Leakage and Penetration

This is the most core application of custom-shaped special rubber rings. Targeting the irregular cavities, special-shaped flanges, customized joints and other structures of non-standard equipment, custom-shaped special rubber rings can fully fit the contact surfaces and block the leakage or intrusion of gas, liquid and dust.

-

Fluid Sealing: Prevent the leakage of media such as oil, water and compressed air in hydraulic systems, pneumatic components, pumps and valves.

-

Dust Sealing: Block external dust and impurities from entering the equipment interior, and protect the operation accuracy of precision components.

Shock Absorption and Buffering to Reduce Noise and Damage

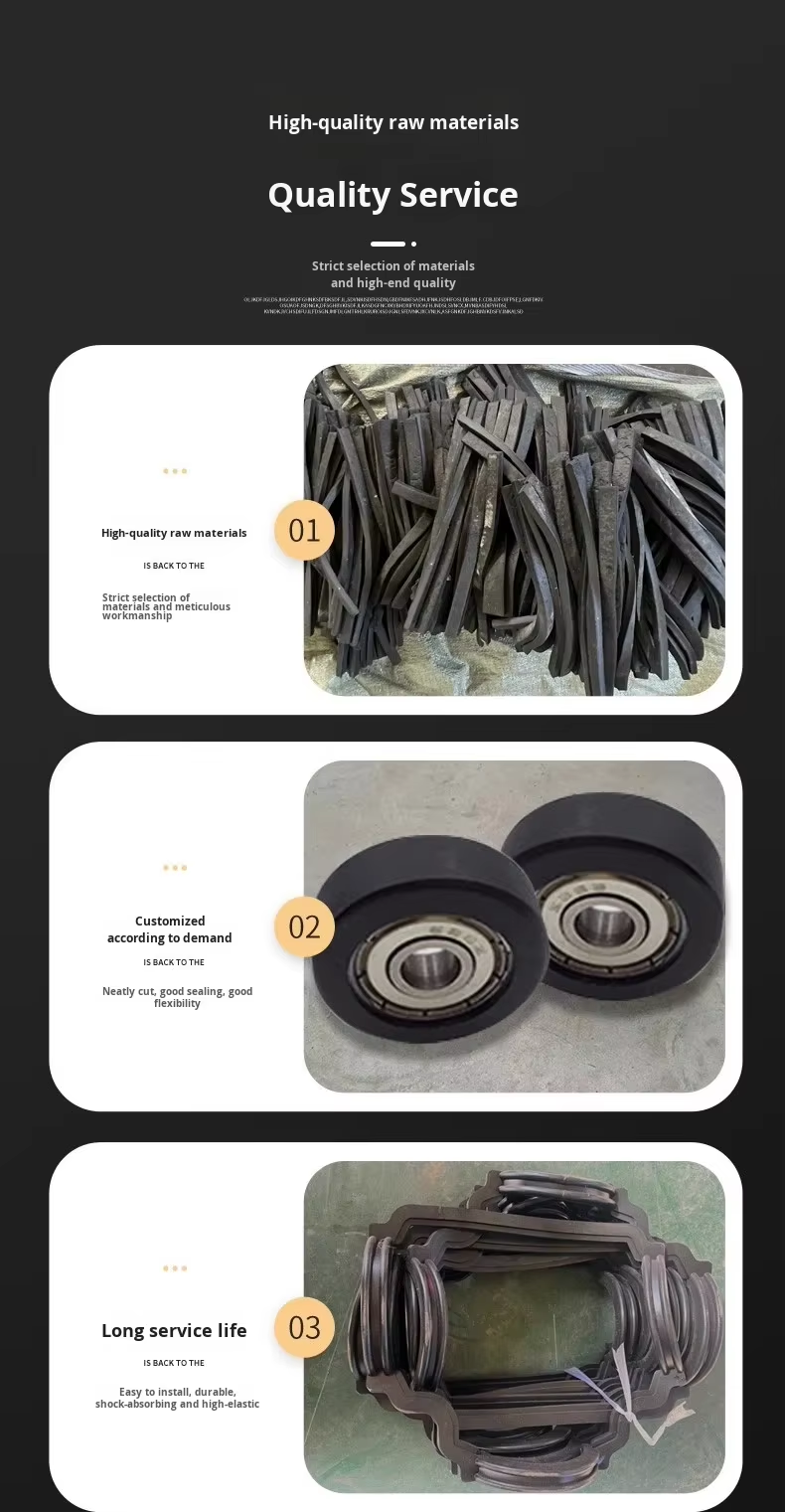

Custom-shaped special rubber rings can be customized in shape and hardness according to the stress points and vibration directions of the equipment, absorb the vibration and impact generated during equipment operation, reduce the noise caused by component friction, and extend the service life of the equipment.For example, in the special-shaped connection parts of motors, compressors and engineering machinery, custom rubber rings can buffer mechanical vibration and reduce rigid collision between components;In the non-standard joints of pneumatic components, custom-shaped rubber rings can buffer air flow impact and stabilize air pressure transmission.

Adapting to Non-standard Structures to Improve Assembly Compatibility

Many industrial equipment have non-circular and irregular installation grooves or connection parts due to functional design requirements, which standard circular rubber rings cannot match. Custom-shaped special rubber rings can fully fit the size and shape of these non-standard structures, avoid sealing failure, component deformation and other problems caused by forced assembly, and improve the stability and compatibility of the overall assembly.

Withstanding Special Working Conditions to Enhance Environmental Adaptability

In addition to shape customization, rubber materials (such as nitrile rubber, fluororubber, silica gel, etc.) can be selected according to working condition requirements, so that custom-shaped special rubber rings have the characteristics of high and low temperature resistance, oil resistance, acid and alkali resistance, corrosion resistance, etc., to adapt to harsh working environments:

-

Fluororubber Special-shaped Rings: Suitable for chemical and high-temperature equipment, resistant to strong corrosive media and high temperatures above 200℃.

-

Silica Gel Special-shaped Rings: Suitable for food and medical equipment, resistant to high and low temperatures, non-toxic and odorless.