EPDM Top & Side Bulb Rubber Sealing Strips: Functions

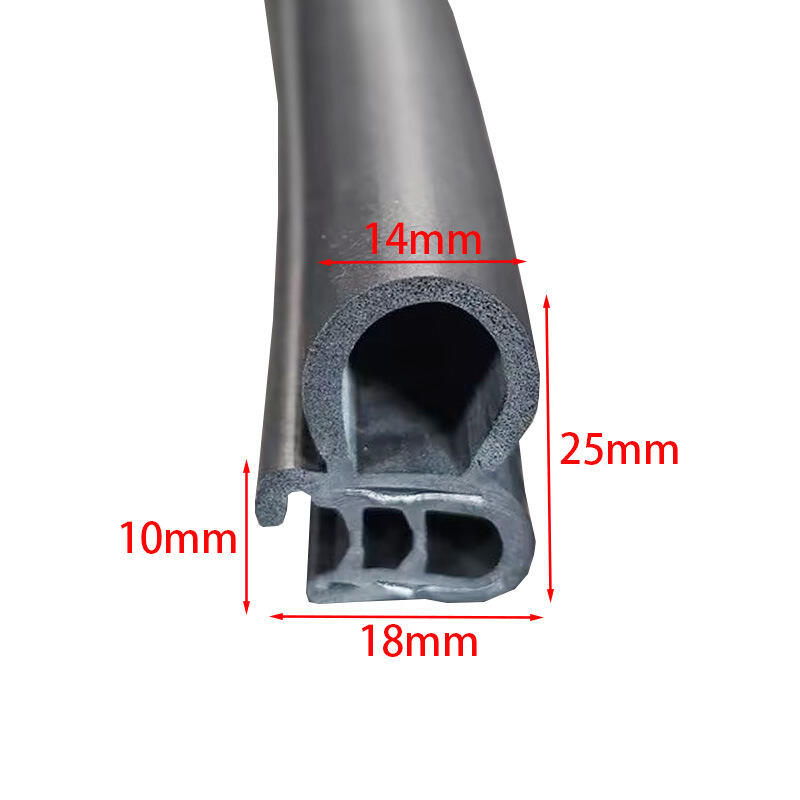

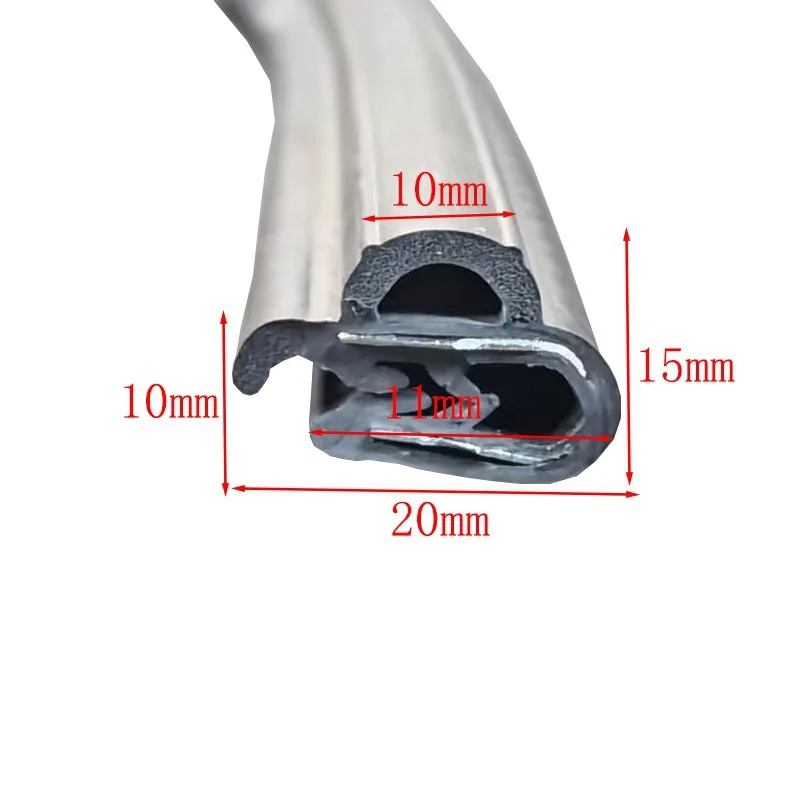

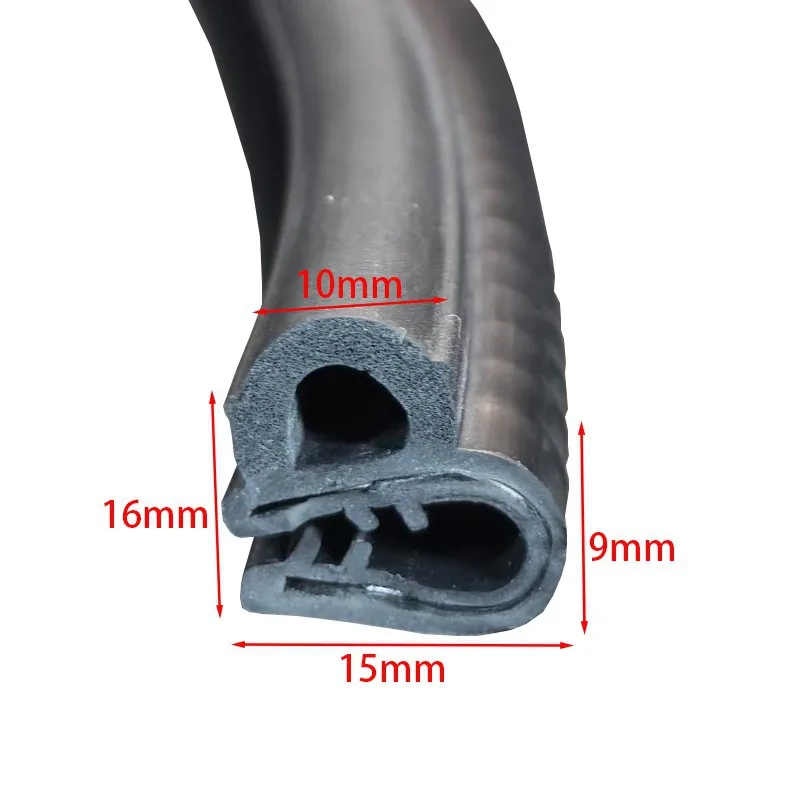

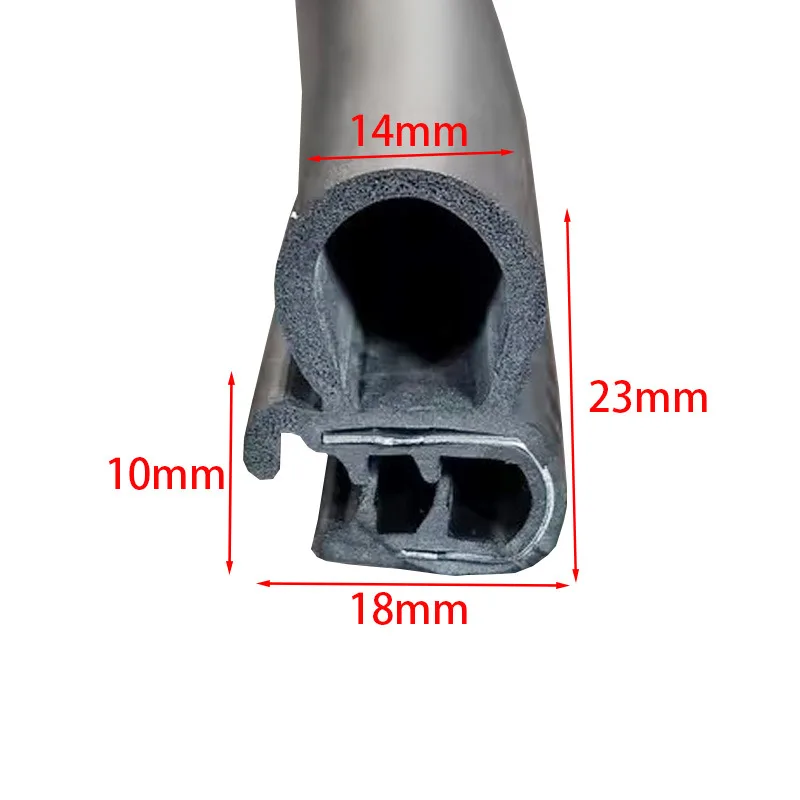

EPDM (Ethylene Propylene Diene Monomer) top & side bulb rubber sealing strips are profiled elastic seals specially designed for gap filling and sealing protection. The "top bulb" refers to the raised bulb that fits against the sealing surface, while the "side bulb" is the lateral bulb for auxiliary positioning or enhanced sealing. Leveraging EPDM’s properties of weather resistance, aging resistance, ozone resistance, and wide temperature tolerance, their core functions are multi-dimensional sealing protection, shock absorption and buffering, sound and heat insulation. They are widely used in automotive, rail transit, door/window curtain walls, industrial equipment and other fields.

I. Core Functions and Application Scenarios

1. Multi-dimensional Sealing for Waterproofing, Dustproofing and Leak Prevention

The composite structure of top bulb + side bulb can fit two or more sealing surfaces simultaneously, forming a three-dimensional sealing barrier with more stable performance than single-bulb sealing strips:

-

Automotive field: Sealing strips for door frames, trunk lids and engine compartment covers. The top bulb presses tightly against the body sheet metal, and the side bulb clamps into the door groove, blocking rainwater, dust and muddy water from entering the car cabin or engine compartment, thus protecting interior trim and electronic components. For window channel sealing strips, the side bulb fits the glass surface, and the top bulb presses the channel inner wall to prevent rainwater leakage and abnormal noise during glass lifting/lowering.

-

Door, window and curtain wall field: Sealing strips for broken bridge aluminum doors/windows and uPVC doors/windows. The top bulb fits the window frame, and the side bulb clips into the sash groove, isolating outdoor rainwater, dust and cold air, and improving the air tightness and water tightness of doors and windows.

-

Industrial equipment field: Sealing strips for equipment cabinet doors and electrical control cabinets. The top bulb and side bulb fit the cabinet door and body respectively, preventing dust and moisture from invading and affecting equipment operation, while blocking leakage of internal oil stains.

2. Shock Absorption, Buffering, Collision Prevention and Noise Reduction

The highly elastic bulbs of EPDM can effectively absorb impact force, reducing collision damage and vibration noise:

- When opening or closing car doors, the top and side bulbs deform under pressure, buffering the impact force between the door and body, avoiding scratches and dents caused by hard metal contact, and reducing door-slamming noise at the same time.

- When equipment cabinet doors are closed, the bulb structure can weaken the transmission of vibration generated by equipment operation, reduce noise leakage, and improve the comfort of the operating environment.

3. Sound and Heat Insulation for Energy Conservation and Consumption Reduction

The closed-cell structure inside the bulbs can block air convection and sound transmission paths:

-

Car cabin: Sealing strips fill the gaps between doors and body, reducing the intrusion of wind and road noise during driving, and improving the quietness inside the car. Meanwhile, they block heat exchange between the inside and outside of the cabin, assisting air conditioners in maintaining temperature and lowering energy consumption.

-

Building doors and windows: Block outdoor hot and cold air from infiltrating into the room, reducing energy loss of air conditioners and heating systems, and weakening the transmission of external noise (such as traffic and crowd noise) into the room, improving indoor living comfort.

4. Weather Resistance Protection for Extended Service Life

EPDM itself has a wide temperature tolerance range of -40℃~150℃, with UV resistance, ozone resistance, and acid-alkali corrosion resistance. Even when exposed to outdoor environments with sun, rain, severe cold and intense heat for a long time, it will not harden, crack or deform easily. Compared with ordinary rubber sealing strips, its service life is extended by 3~5 times, which can maintain sealing performance for a long time and reduce maintenance and replacement costs.