T-Shaped Silicone Plugs: Functions and Applications

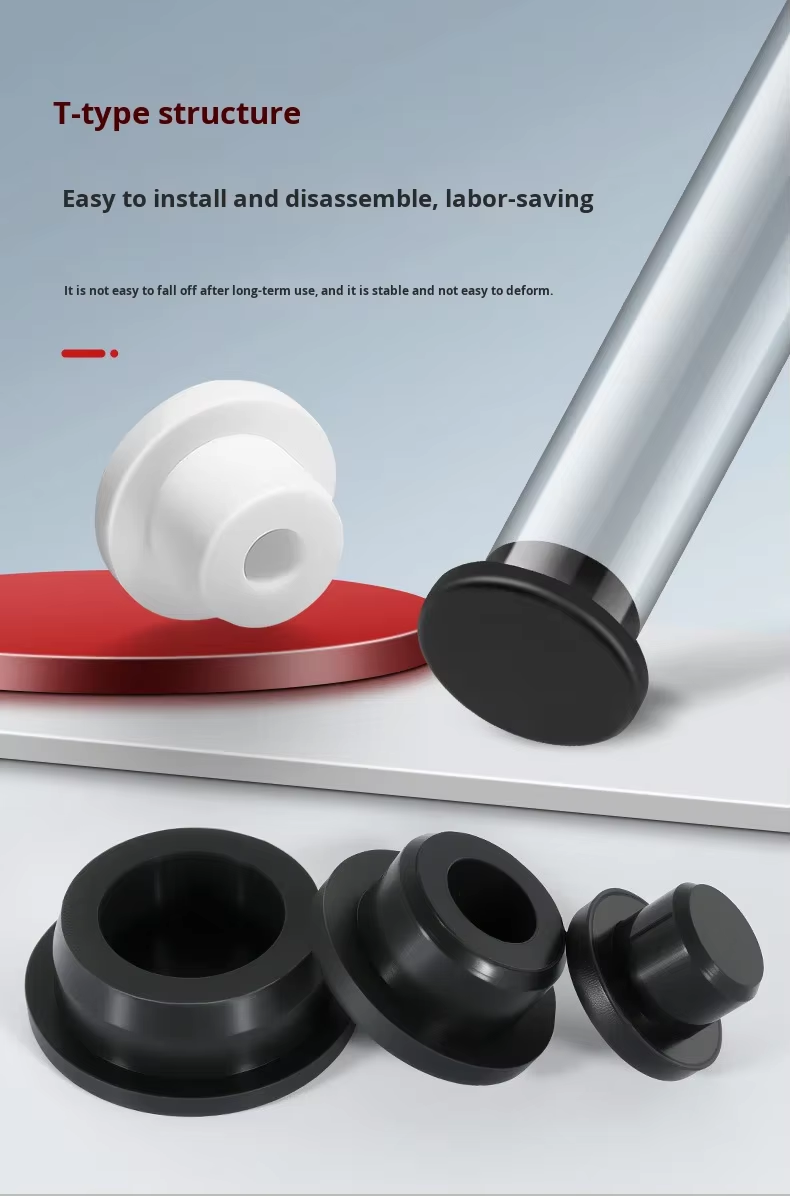

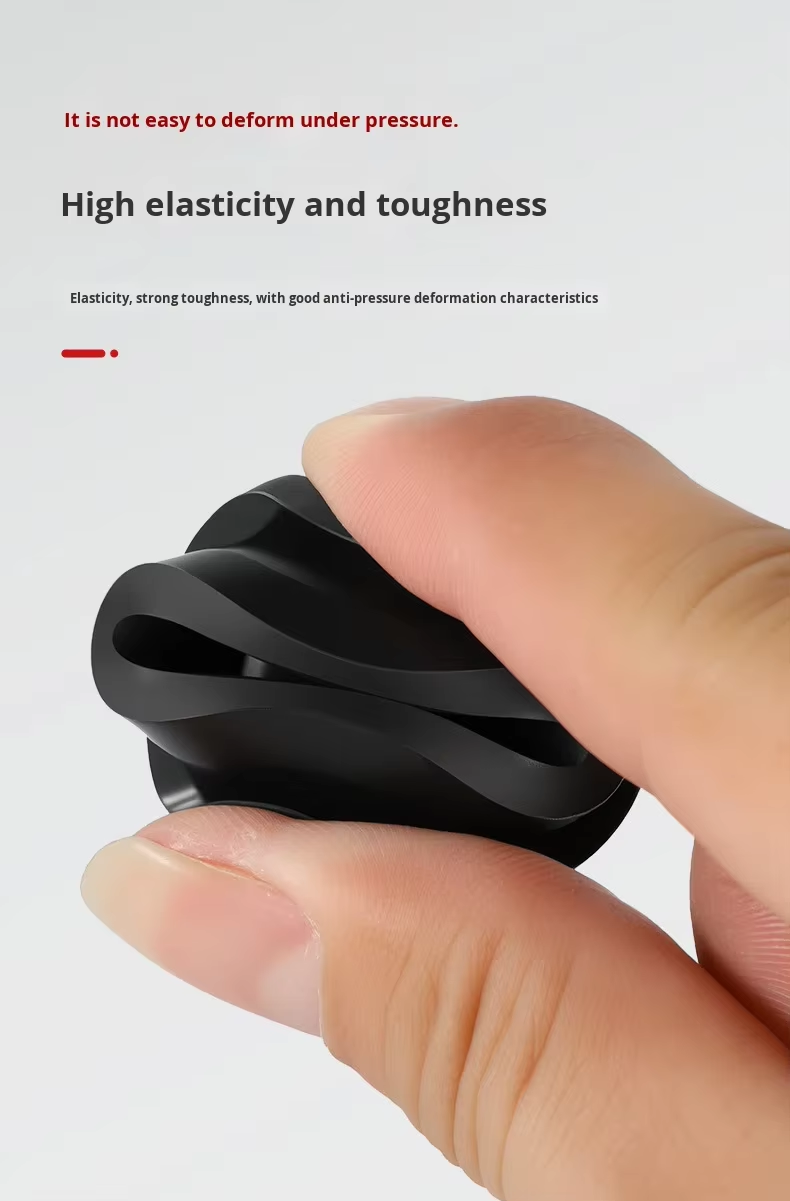

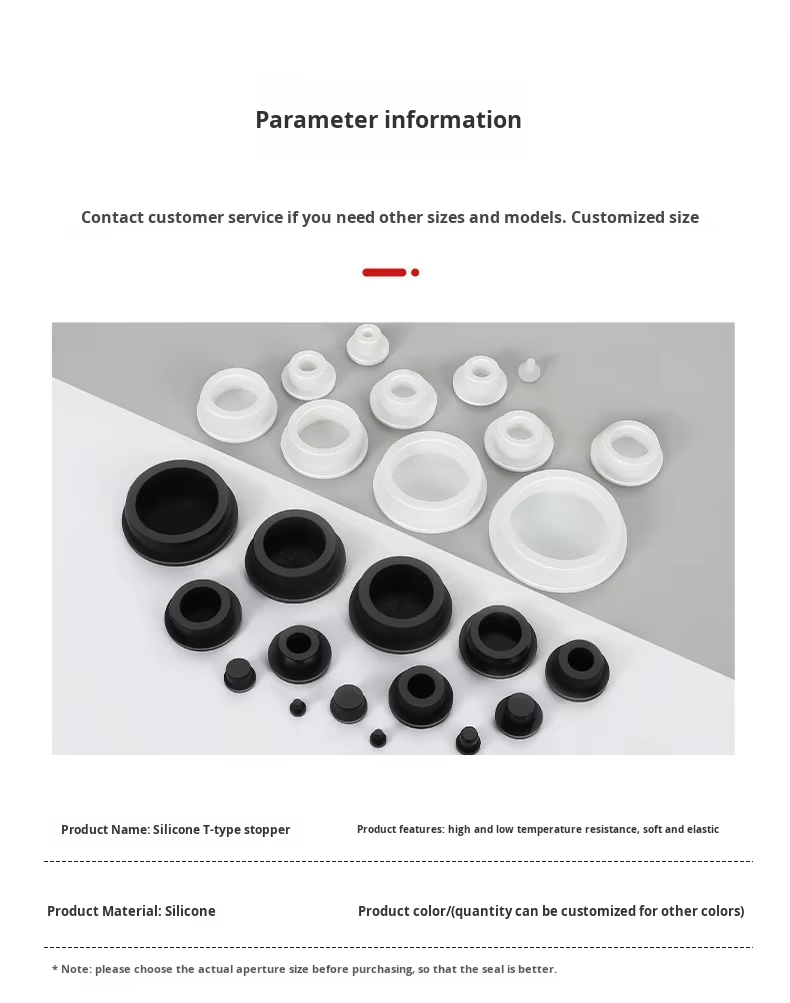

T-shaped silicone plugs are widely used sealing and protective components in industrial fields, named for their T-shaped cross-section. Their core functions include hole sealing, pipeline blocking, dust/waterproofing, and limit buffering. Leveraging silicone’s high elasticity, temperature resistance, and corrosion resistance, they are suitable for multiple scenarios such as pneumatics, hydraulics, electronics, and automotive manufacturing.

I. Core Functions and Application Scenarios

1. Hole Sealing, Dustproofing & Waterproofing

This is their primary function. Insert a T-shaped silicone plug into the reserved holes, process holes, or through-holes on equipment housings, panels, or cylinder blocks. The stepped surface of its T-shaped structure fits tightly against the hole edge, while the cylindrical part fills the hole channel, creating a robust sealing barrier. This prevents external dust, moisture, and oil from entering the equipment interior and avoids leakage of internal media.

Typical Scenarios:

- Sealing process holes on pneumatic component cylinders

- Sealing reserved oil holes in hydraulic equipment

- Dustproofing and waterproofing cooling holes on electronic device casings

2. Temporary Pipeline Blocking & Isolation

They are used for temporary port sealing or sectional isolation in pipeline systems. For example, during pipeline pressure testing, maintenance, or storage, plugs can seal pipeline ports to prevent foreign matter from entering or internal fluid from leaking. They can also block idle branches in multi-branch pipelines to simplify the pipeline layout.

Typical Scenarios:

- Temporary blocking of pneumatic hose and hydraulic oil pipe ports

- Pipeline protection for equipment before factory shipment

3. Limit Buffering, Shock Absorption & Noise Reduction

Silicone has excellent elasticity and wear resistance, allowing T-shaped plugs to serve as lightweight limiters or buffer pads. When equipment components move to their limit positions, the plugs absorb impact force, reduce collision noise, and prevent wear caused by direct contact between metal parts.

Typical Scenarios:

- Limit buffering at the end of piston rods in small cylinders

- Anti-collision positioning of moving components in automated equipment

4. Insulation Protection

Silicone is an excellent insulating material. T-shaped silicone plugs can seal metal holes in electrical equipment, playing a role in insulation and isolation. This prevents current leakage or short circuits, enhancing the operational safety of the equipment.

Typical Scenarios:

- Protection of wiring holes on motor housings

- Insulation and sealing of metal through-holes in electrical control cabinets

II. Advantages of T-Shaped Silicone Plugs

-

Strong Material Adaptability

Silicone has a wide temperature resistance range (

-40℃ to 200℃), along with resistance to weak acids, weak alkalis, and aging. It is not easily deformed, making it suitable for harsh industrial environments.

-

Easy Installation

No additional fasteners are required. They rely on their own elasticity to achieve interference fit with holes, enabling manual push-to-install or removal. This results in low maintenance costs.

Stable Sealing Performance

The "step" of the T-shaped structure effectively prevents the plug from being pushed out by fluid pressure or external force. Its sealing reliability is superior to that of ordinary cylindrical plugs.