But, do you any idea about pneumatic pipe fittings? These are tiny, but integral components that assist in marrying pipes together to form an air pressure system which drives machines. These machines include factories which are producing items like the cars we drive, to even airplanes that fly high in the sky. The machines, without these fittings may not work appropriately.

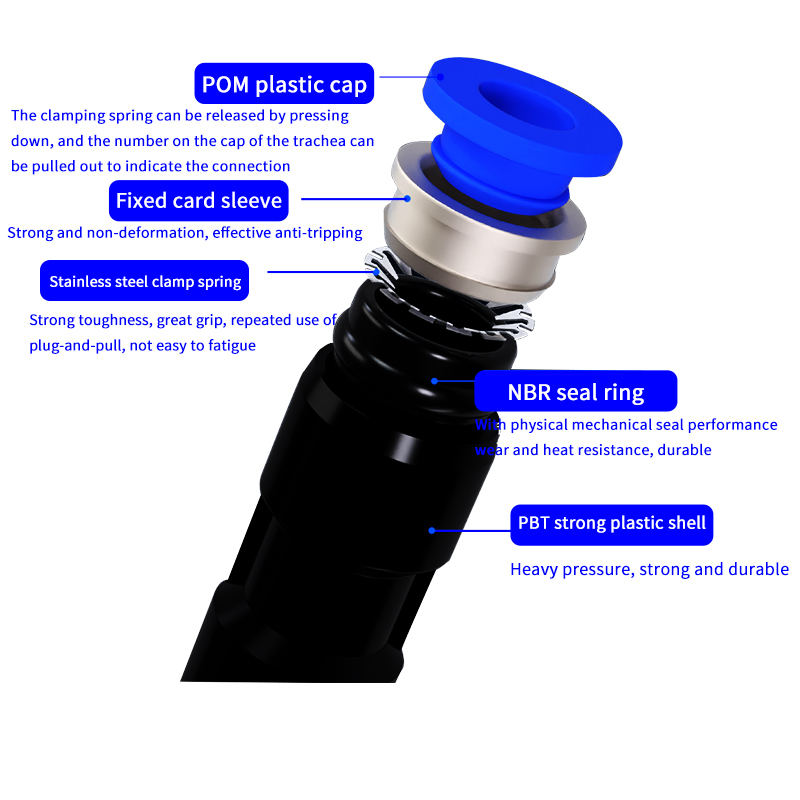

There are many thing to consider when trying to choose the best pneumatic pipe fitting for your job. The very first factor to consider is the pipe size you are using. This is so important because if it fits perfectly you will never have to worry about the pipe trying its best to unscrew itself. A respectively over and under-sized fitting won't do you any good. To begin with, you must know that there are various connector types for your pipes. Fittings take many forms, including elbows, tees and couplings. Every type has its own purpose and is used to enable pipes in a different manner. Last but not least it is very important to select a fitting that can stand the air pressure generated by your system. It may shatter or have complications if the fitting cannot withstand pressure.

Pneumatic Pipe Fittings Keep Us Moving Smoothly They are important because the keep machines to work in a smooth and reliable way. Without these fittings, pipes could breakdown and allow air to escape. This creates leaks cause out machines to stop running or not work properly Correct Fittings - increase the efficiency of your system and help it to perform better. That not only keeps the machines running but helps you save some money by stopping air leaks that waste energy.

Pneumatic pipe fittings can sometimes become problematic. For instance, one of the major issue that is likely to develop with these kitchen gadgets is their tendency to leak air. This would cause the machines to stop, or continue working but not doing their job correctly. If you find a defect of this nature, it is crucial that every connection in your system be thoroughly evaluated. Check to see if any are damaged and replace them You can also assess the pressure of your system using a manometer, another specialized tool. This tool allows you to figure out where the issue is so you can quickly fix it and get your machines working like they should again.

There have also been much more futuristic advancements in the realm of pneumatic pipe fitting technology over recent years, as well. Advancements in material technology have led to new materials which are lighter, stronger and more durable. Material upgradation leads to manufacture of more durable and better performing fittings. The other important aspect is that new manufacturing practices allow for very well manufactured fittings at a lower cost. What that means is this makes it so companies can make higher quality machines in turn making them more efficient and reliable, a win-win for sure.

Our professional team and business professionals provide complete support and pneumatic pipe fittings to our customers. It starts with consulting on the product, processing of orders and finishing with after-sales support. Help customers decide on the most appropriate products by utilizing professional knowledge and effective customer relationship management.The company employs a group consisting of design engineers and developers, modern offices, standardized workshops, and cutting-edge production technology. It's a high-tech enterprise that integrates scientific research, development and production. The company is staffed by a team that is highly trained and professional sales engineers and design engineers to provide superior solutions and services to customers.

Suzhou Edith Electronics Co., Ltd. has a long-standing history and years of experience, backed by top technology and modern production equipment to meet the constantly changing demands of customers. Our company is dedicated to providing top-quality products, pneumatic pipe fittings, and research that helps develop the industry's development of pneumatic parts. To make their customers more satisfied The vacuum cup maker always strives to improve technology, offers customers top-quality products and enhances the pre-sales as well as after-sales support. Our mission is to "pursue excellence, and give priority to customer service and possess top technology".

Suzhou Edith Electric Co., Ltd. manufactures vacuum suctions cups for manipulators fixtures ( pneumatic pipe fittings) holding tools, jigs, as well as other automation-related accessories. Its products have been widely used by the new energy industry, tunnels as well as aviation, steel and glass packaging, automotive electronics food, daily chemical, printing, and other industries. The company follows the business philosophy of "technology first innovative thinking, pragmatic innovation, customers first and customer service first" reflecting the value of warmth in service, while improving customer satisfaction as the primary direction, and pursuing the most perfect customer service.

We are able to customize our products to meet the needs of each customer This makes us distinct from our competitors. It is more pneumatic pipe fittings, offers greater quality, and can satisfy the needs of the customers. It provides a complete and efficient after-sales service. To order custom products, clients must submit drawings or physical objects, and we will provide quotations based on the pictures or tangible objects. We also offer no-cost samples, but you won't be charged for freight. After paying the deposit and we'll arrange the customized products and ship them as soon as possible. Delivery time for customized items generally takes between 15 and 30 days, depending on the quantities.

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy