|

Place of Origin: |

CHINA |

|

Brand Name: |

Edith |

|

Model Number: |

PZA6/8/10/12 |

|

Minimum Order Quantity: |

Negotiable |

|

Price: |

Negotiable |

|

Packaging Details: |

Carton package/Wooden cases |

|

Delivery Time: |

Depending on the order quantity |

|

Payment Terms: |

L/C, T/T |

|

Supply Ability: |

Negotiable |

|

Disc diameter |

Customized Accepted |

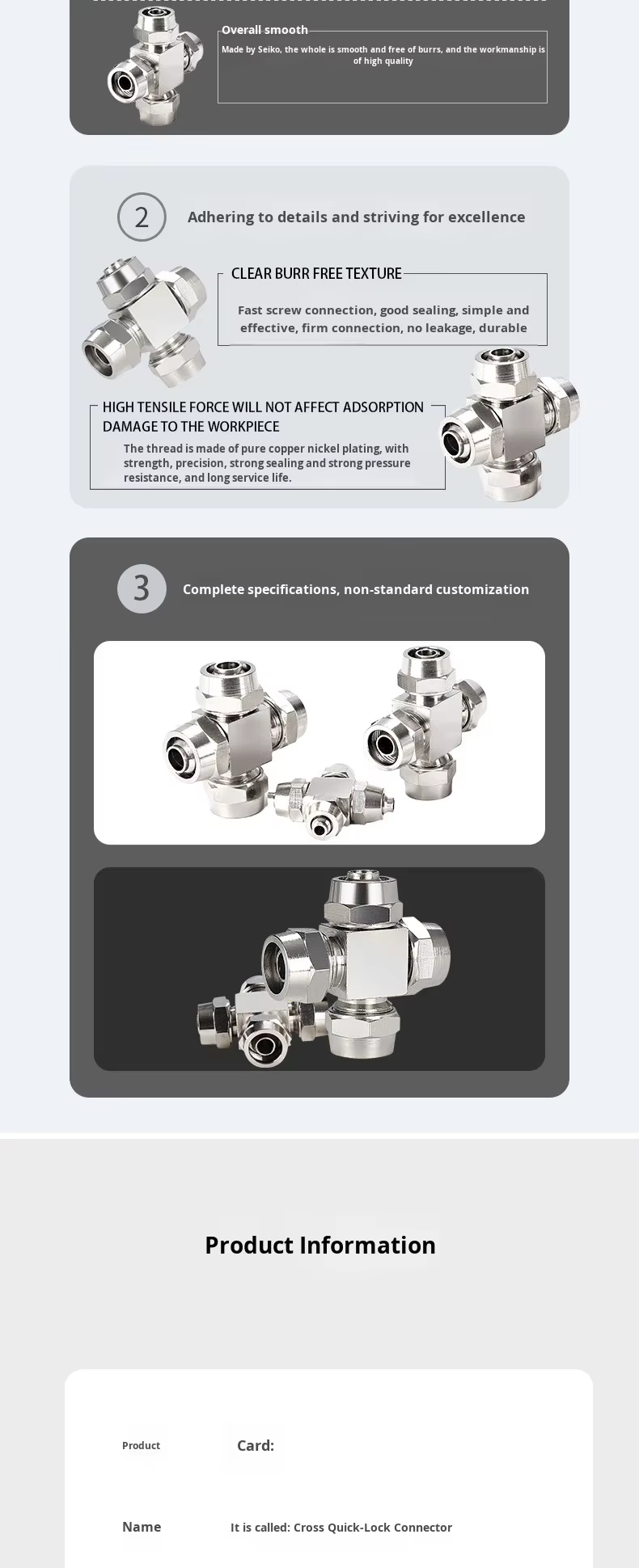

Material: |

Copper |

|

Highlight 1: |

Not easily deformed |

Highlight 2: |

Anti-Aging Insulated |

|

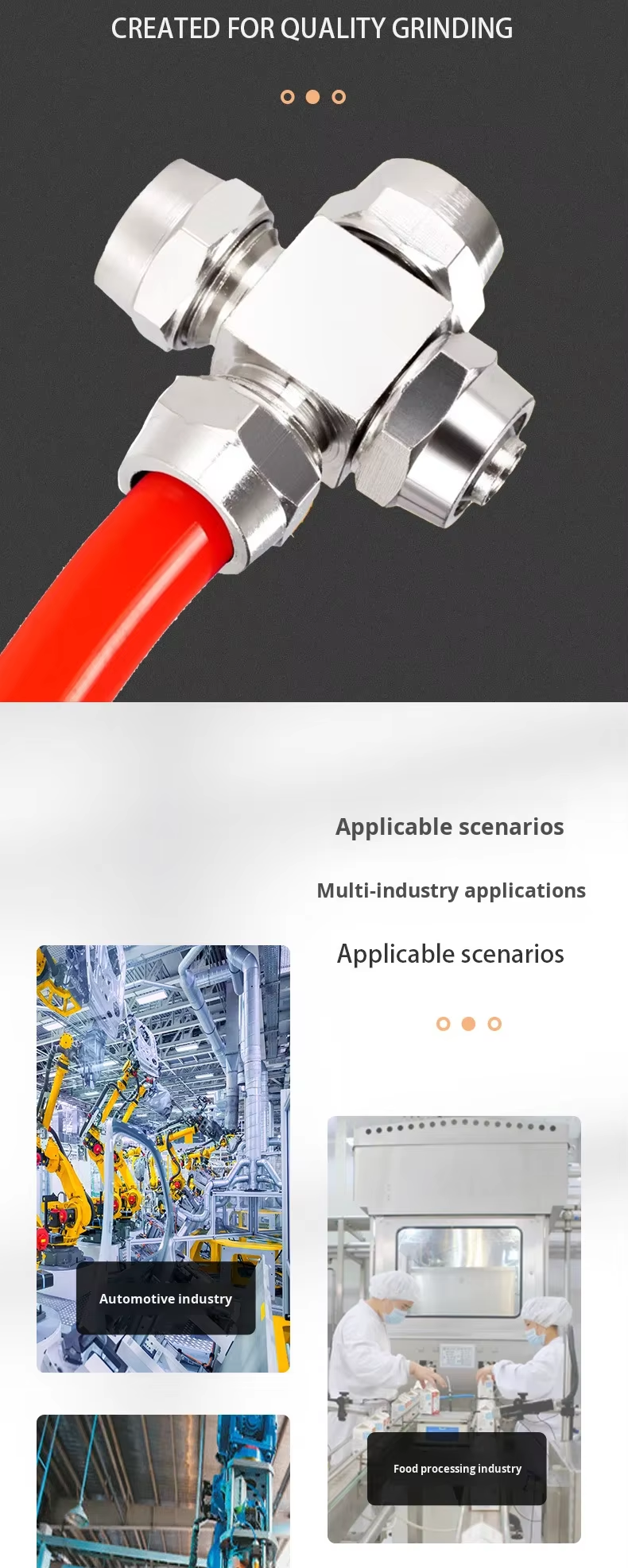

Application: |

Industry |

Name: |

Cross Quick-Connect Fitting |

|

High Light: |

High-Temperature Resistant |

||

Process Steps |

ODM |

ODM |

Step 1 |

CustomerRequirement |

CustomerRequirement

|

Step 2 |

SchemeAppraisal |

SchemeAppraisal

|

Step 3 |

ProfileConfirmation(Packing Dimension Functional)

|

Negotiation Cooperation

|

Step 4 |

Sample Design |

Quote

|

Step5 |

Small BatchProduction

|

Sample Confirmation

|

Step 6 |

Product Confirmation

|

Small Batch Production

|

Step7 |

- |

Product Confirmation |

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy