Process Steps |

ODM |

ODM |

Step 1 |

CustomerRequirement |

CustomerRequirement

|

Step 1 |

SchemeAppraisal |

SchemeAppraisal

|

Step 1 |

ProfileConfirmation(Packing Dimension Functional)

|

Negotiation Cooperation

|

Step 1 |

Sample Design |

Quote

|

Step 1 |

Small BatchProduction

|

Sample Confirmation

|

Step 1 |

Product Confirmation

|

Small Batch Production

|

Step 1 |

- |

Product Confirmation

|

The MGPM20 series is a compact thin-type triple-axis cylinder with guide rods, featuring a 20mm bore size, belonging to SMC's MGP-Z series. Its core advantages include compact and thin profile, built-in guide rods to prevent rotation, and high rigidity, making it suitable for space-constrained scenarios such as automated assembly and small-scale material handling. Below is a detailed introduction to the MGPM20-20/30/40/50/100/125 models.

-

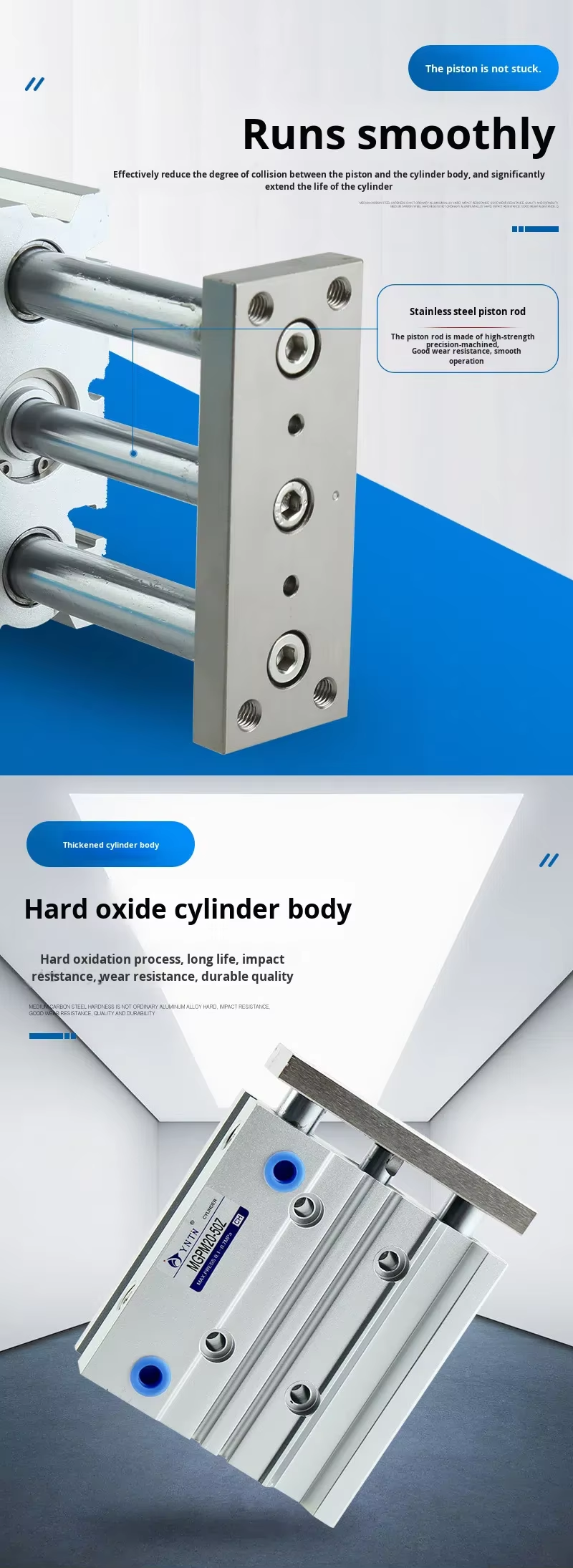

Core Type: Single-rod double-acting, thin-type triple-axis cylinder with guide rods, equipped with built-in sliding bearings. The non-rotation accuracy is ±0.07°. A built-in magnetic ring allows for the installation of magnetic switches.

-

Structural Features: The triple-axis guide rod design disperses load and prevents piston rod deflection. The slim body saves installation space, with polyurethane cushioning on both sides for shock absorption. The cylinder barrel, end caps, and piston are made of aluminum alloy, while the piston rod is stainless steel—ensuring overall lightweight and durability.

-

Model Nomenclature: MGPM20-S (where S denotes stroke length, e.g., 20 = 20mm, 125 = 125mm). The common suffix Z indicates the standard model, and M indicates the lubrication retention function. Versions with end locks or pneumatic cushioning can be customized upon request.

Note: Thrust is calculated using the formula F=P×A (where A is the effective piston area, approximately 301.6mm² for a 20mm bore size). Actual thrust is affected by pressure, speed, load, and other factors.

-

Typical Applications: 3C electronic assembly, automated dispensing/screw locking, small part handling, testing equipment positioning, light industry packaging lines, and other space-limited automated scenarios.

-

Selection Tips:

- Select models based on load weight and stroke requirements. Choose short-stroke models for light-load, high-frequency operations; opt for 100/125mm strokes for handling tasks based on distance needs.

- For precise rotation prevention or high-frequency movement, upgrade to the MGPA series with high-precision ball bearings.

- For position locking requirements, select versions with end locks; for enhanced cushioning, add external hydraulic buffers.

-

Installation Methods: Supports multiple mounting options including top, side, bottom, and T-slot side mounting, adapting to different equipment layouts.

-

Maintenance Tips: Regularly check for piping leaks and maintain dry, clean air supply. For long-term high-frequency use, periodic lubrication is recommended (even for oil-free models, minimal lubrication can be applied as needed).

-

item |

value |

Action Method |

Double Action |

Place of Origin |

China |

|

Jiangsu |

Connection Type |

Consult customer service |

Type |

Cyinder with Guide Rod |

Direction of rotation |

No Rotation |

Buffering Type |

Self-regulating air buffe |

Color |

Silver |

Feature |

Strong adsorption |

Service |

Customized Services |