| প্রক্রিয়ার ধাপসমূহ |

ওডিএম |

OEM |

| ধাপ 1 |

গ্রাহকের প্রয়োজন |

গ্রাহকের প্রয়োজন |

| ধাপ ২ |

প্রাক্কলন মান |

প্রাক্কলন মান |

| ধাপ ৩ |

প্রোফাইল নিশ্চিতকরণ (প্যাকিং মাত্রা কার্যকরী )

|

আলোচনা সহযোগিতা |

| ধাপ ৪ |

নমুনা ডিজাইন |

প্রস্তাব |

| ধাপ ৫ |

ছোট ব্যাচ উৎপাদন |

নমুনা নিশ্চিতকরণ |

| ধাপ 6 |

পণ্য নিশ্চিতকরণ |

ছোট ব্যাচ উৎপাদন |

| ধাপ 7 |

- |

পণ্য নিশ্চিতকরণ |

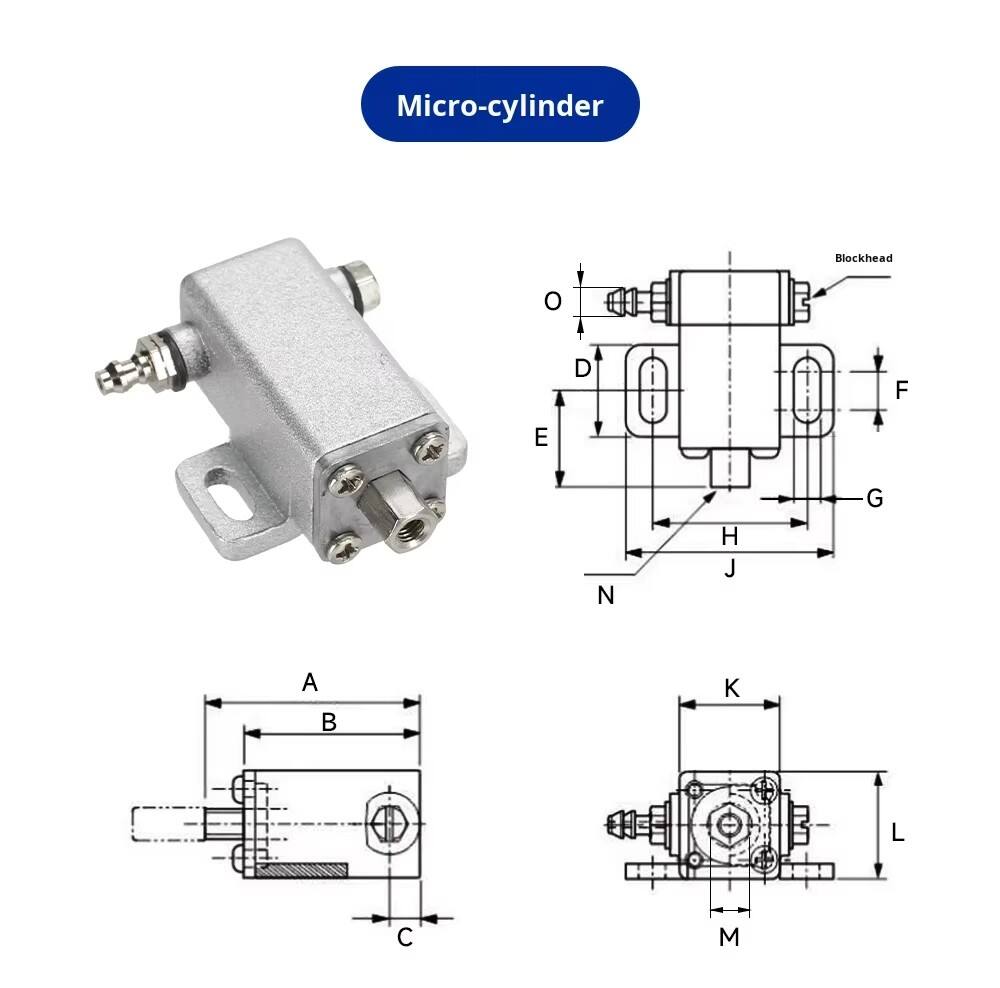

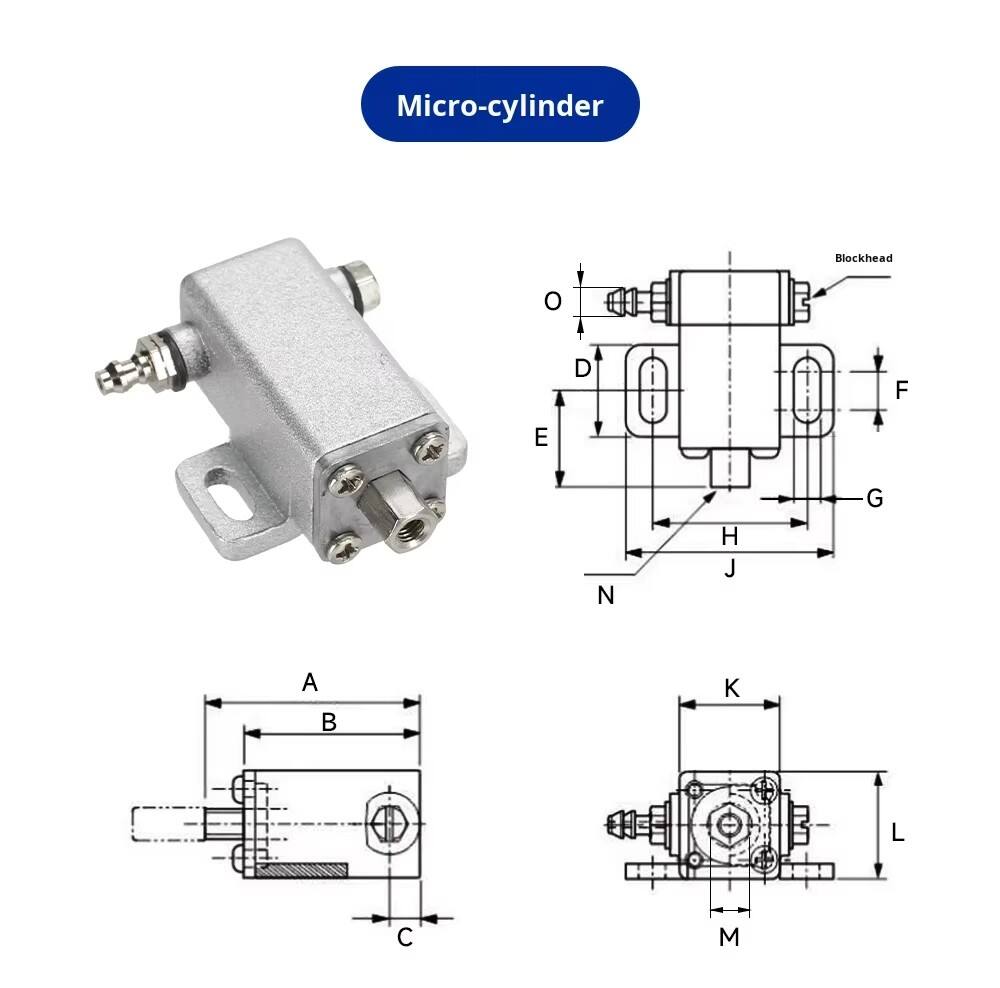

UMCD10 হলো এইন্স ব্র্যান্ডের একটি মাইক্রো সিলিন্ডার, যা ছোট আকারের নির্ভুল ক্ল্যাম্পিং কাজের উপর ফোকাস করে এবং ছোট আকারের কাজের টুকরো নিয়ে কাজ করা প্রবাহী নিয়ন্ত্রণ পরিস্থিতিতে ব্যবহারের জন্য উপযুক্ত। এর নির্দিষ্ট কাজ এবং অভিযোজন বৈশিষ্ট্যগুলি নিম্নরূপ:

একটি এক-ক্রিয়াকারী মাইক্রো সিলিন্ডার হিসেবে, এর মূল কাজ হলো ছোট আকারের মডেলড অংশগুলি ক্ল্যাম্প করার জন্য বিশেষভাবে অভিযোজিত হওয়া। ০.৪৯ এমপিএ কাজের চাপে এর আউটপুট বল ৩৯ এন পর্যন্ত পৌঁছায় এবং এটি ০.৩–০.৫ এমপিএ সাধারণ কাজের বায়ু চাপ পরিসরের মধ্যেও স্থিতিশীলভাবে শক্তি সরবরাহ করতে পারে। এটি ছোট ইনজেকশন-মোল্ডেড অংশ এবং মাইক্রো হার্ডওয়্যার উপাদানের মতো হালকা ও পাতলা ছোট কাজের টুকরোগুলিকে সঠিকভাবে ও দৃঢ়ভাবে ক্ল্যাম্প করতে পারে, যা নির্ভুল যন্ত্রকর্ম এবং ইলেকট্রনিক অ্যাসেম্বলির মতো পরিস্থিতিতে ছোট কাজের টুকরোগুলির অবস্থান নির্ধারণ ও স্থিরীকরণের প্রয়োজনীয়তা পূরণ করে।

এটি বিশেষ আকর্ষণ ফিক্সচার (যেমন XL0010-105 এবং CP-063A) এর সাথে মিলিয়ে নেওয়া যেতে পারে, এবং সিলিন্ডারের সামনের প্রান্তে একটি আকর্ষণ প্যাড ইনস্টল করা যেতে পারে যাতে আকর্ষণ কার্যকারিতা বৃদ্ধি পায়। এই সংমিশ্রণটি আরও হালকা, পাতলা এবং সহজেই ক্ষতিগ্রস্ত হওয়া ছোট কাজের টুকরোগুলির সাথে খাপ খাইয়ে নিতে পারে, অত্যধিক চাপ দেওয়ার ফলে কাজের টুকরোর ক্ষতি এড়ায় এবং সূক্ষ্ম ইলেকট্রনিক উপাদান ও মাইক্রো প্লাস্টিক অংশগুলির মতো বিশেষ ছোট কাজের টুকরোগুলির পিক-অ্যান্ড-প্লেস অপারেশনের জন্য উপযুক্ত।

সিলিন্ডারটিতে সিলিন্ডার রড ঘূর্ণন-প্রতিরোধী গঠন রয়েছে, যা টেলিস্কোপিক ট্রান্সমিশন প্রক্রিয়ায় পিস্টন রডের ঘূর্ণন ও বিচ্যুতি রোধ করতে পারে, চাপ দেওয়া বা আকর্ষণের সময় অবস্থানের নির্ভুলতা নিশ্চিত করতে পারে, পিস্টন রডের বিচ্যুতির কারণে ছোট কাজের টুকরোগুলির চাপ দেওয়ার সময় বিচ্যুতি এড়াতে পারে এবং পরবর্তী অ্যাসেম্বলি, মেশিনিং ও অন্যান্য প্রক্রিয়াগুলির নির্ভুলতা নিশ্চিত করতে পারে।

এটি একটি ছোট ও কমপ্যাক্ট আকারের (প্রস্থ ২৭ মিমি, গভীরতা ৩৩ মিমি, উচ্চতা ১৪ মিমি) এবং এতে ২টি M3 মাউন্টিং বোল্ট ও ৩.৫×৫ মাউন্টিং হোল রয়েছে, যা কমপ্যাক্ট সরঞ্জাম বা টুলিং স্পেসে ইনস্টলেশনকে সহজতর করে। একইসাথে, এটি φ৪ মিমি সংযোগ হোস সহ সামঞ্জস্যপূর্ণ এবং M3 পাইপিং সংযোগ গ্রহণ করে, যার ফলে এটি অতিরিক্ত ইনস্টলেশন স্পেস না দখল করেই ছোট বায়ুচালিত সিস্টেমে নমনীয়ভাবে একীভূত হতে পারে, বিভিন্ন মাইক্রো সরঞ্জামের পাইপলাইন লেআউটের প্রয়োজনীয়তা পূরণ করে।

| আইটেম |

মান |

| প্রযোজ্য শিল্প |

মেশিন নির্মাণ কারখানা, ভবন উপকরণের দোকান, খাদ্য ও পানীয় কারখানা, খাদ্য দোকান, বিজ্ঞাপন কোম্পানি |

| ওজন (কেজি) |

0.2 |

| শোরুমের অবস্থান |

উপলব্ধ নয় |

| যন্ত্রপাতি পরীক্ষার প্রতিবেদন |

উপলব্ধ নয় |

| বিপণন প্রকার |

সাধারণ পণ্য |

| উৎপত্তিস্থল |

চীন |

| অবস্থা |

নতুন |

| ওয়ারেন্টি |

1 বছর |

| পণ্যের নাম |

UMCD-10 |

| আবেদন |

বায়ুচাপ পদ্ধতি |