|

مكان المنشأ: |

الصين |

|

اسم العلامة التجارية: |

إديث |

|

رقم الطراز: |

موصل مستقيم بخيط M10x1 و1/8 بوصة |

|

كمية الطلب الأدنى: |

قابل للتفاوض |

|

السعر: |

قابل للتفاوض |

|

تفاصيل التغليف: |

تعبئة الكرتون/صناديق خشبية |

|

وقت التسليم: |

اعتمادا على كمية الطلب |

|

شروط الدفع: |

L/C، T/T |

|

قدرة التوريد: |

قابل للتفاوض |

|

قطر القرص |

مخصصة مقبولة |

الخامات: |

نحاس مطلٍ بالنيكل |

|

الخاصية الرئيسية 1: |

لا يتشوه بسهولة |

الخاصية الرئيسية 2: |

مضاد للشيخوخة وعازل |

|

التطبيق: |

الصناعة |

الاسم: |

- |

|

إضاءة عالية: |

مقاوم للحرارة العالية |

||

خطوات العملية |

ODM |

ODM |

الخطوة 1 |

متطلبات العميل |

متطلبات العميل

|

خطوة 2 |

تقييم المخطط |

تقييم المخطط

|

خطوة 3 |

تأكيد الملف (التغليف الأبعاد، الوظيفة )

|

التفاوض التعاون

|

خطوة 4 |

تصميم العينة |

اقتباس

|

خطوة 5 |

إنتاج دفعة صغيرة

|

عينة تأكيد

|

خطوة 6 |

منتج تأكيد

|

مجموعة صغيرة إنتاج

|

خطوة 7 |

- |

منتج تأكيد |

العنصر |

القيمة |

دعم مخصص |

OEM |

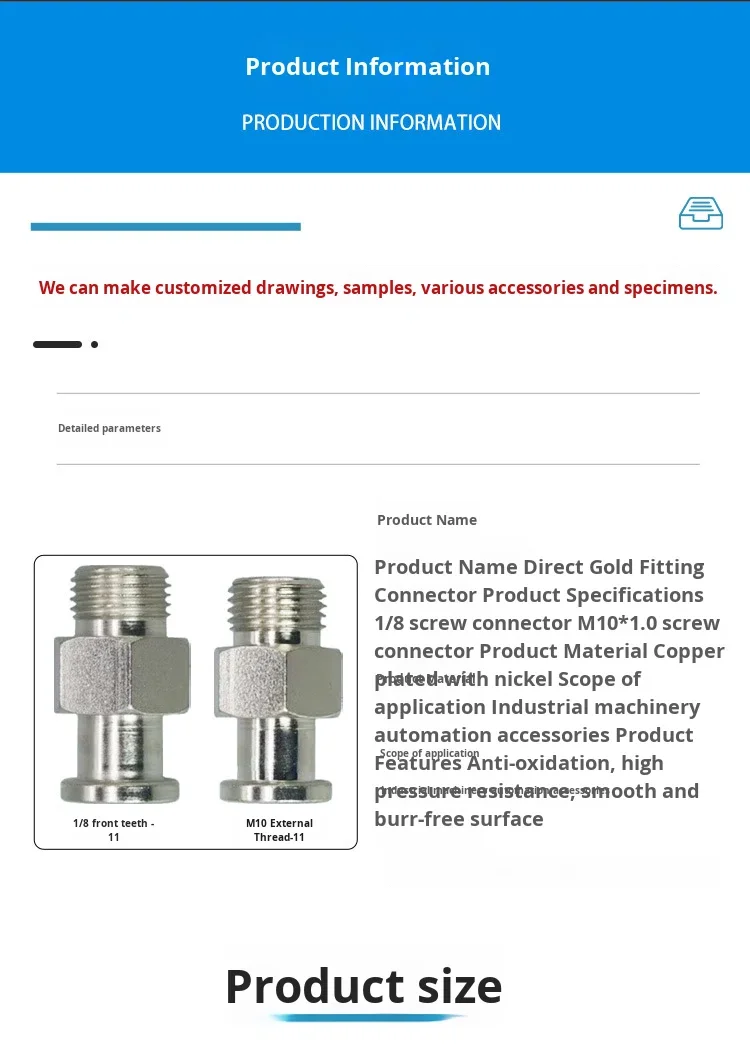

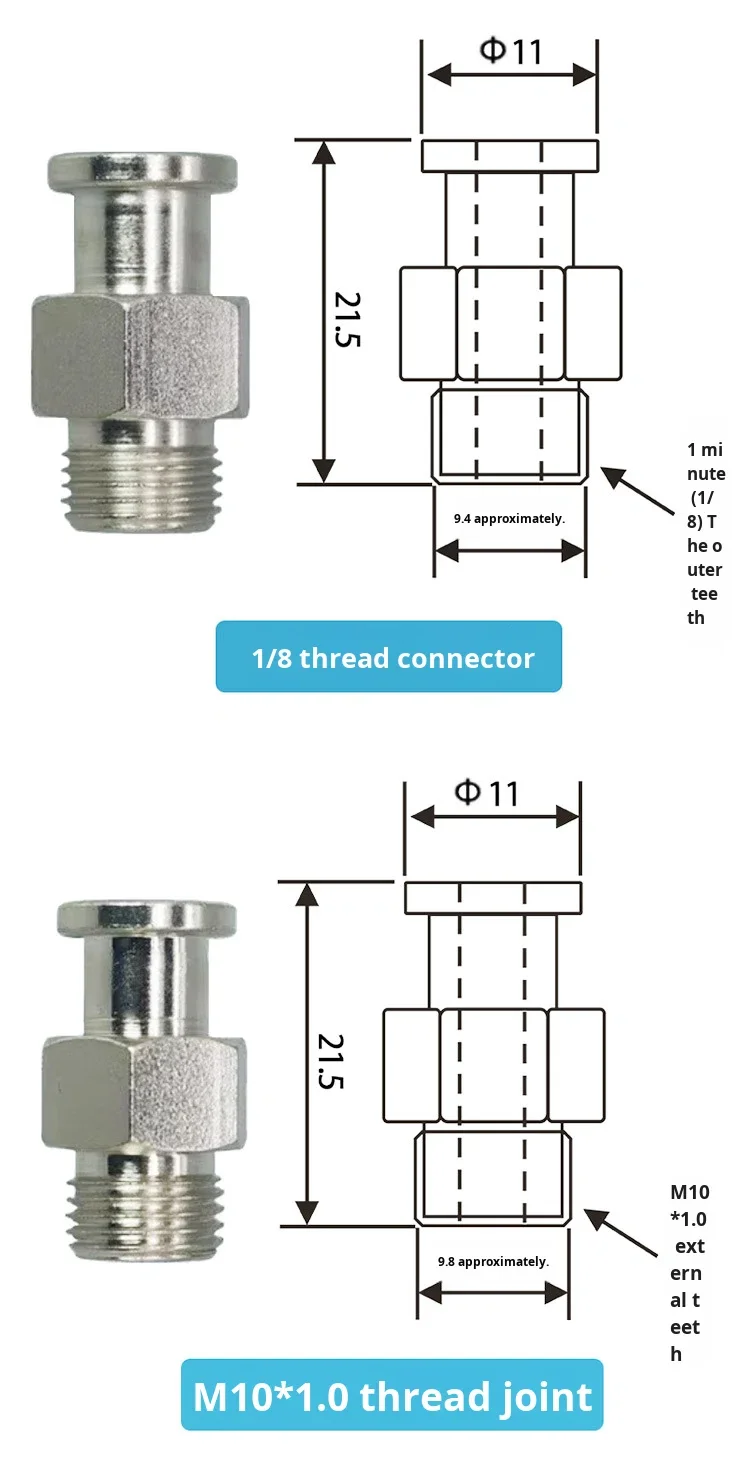

مواصفات المنتج |

وصلة خيطية 1/8 بوصة / وصلة خيطية M10×1.0 |

مادة المنتج |

طلاء نحاسي مع نيكل |

نطاق التطبيق |

ملحقات أتمتة الآلات الصناعية |

مميزات المنتج |

مقاوم للأكسدة، ومقاوم للضغط العالي، وسطح أملس خالٍ من الحواف الحادة |

التطبيق |

ذراع روبوت صناعي |

الخدمة |

خدمات مخصصة |

المواصفات |

معيار |

الحزمة |

صناديق كرتونية، إلخ. |

الوزن |

0.1 |

حقوق النسخ © شركة سوزهو إديث إلكترونيكس المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية