Pin Clamp Cylindrical Are you simply pin clamping cylinder. A somewhat unique tool that esentially holds implants in place using minature pins. So now we will study what pin clamp cylinders are, why they help and how to take care of it as well. We have also explained here the use of these in various jobs through this text8055 Well, let us begin and explore more about this helpful tool!

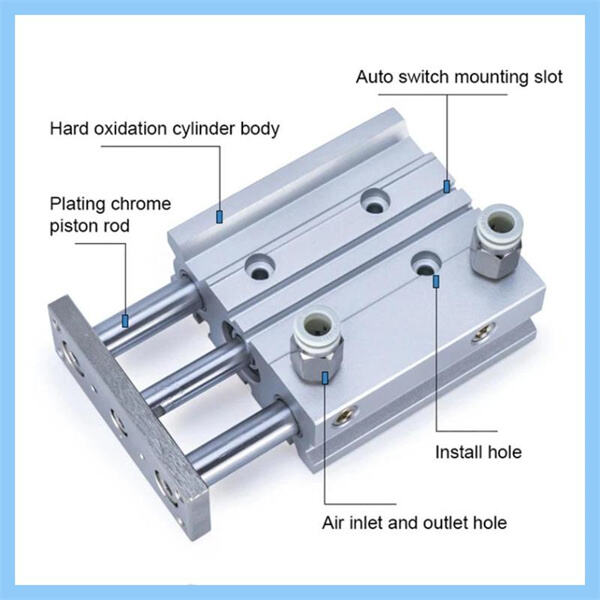

The device that securely holds something with the support of pins is known as a pin clamp cylinder. So, this device has a component that is known as the piston which reciprocates inside it. The pins are pushed in and out as the piston moves. It enables you to grip onto items and hold them properly. As the pins are driven into place they ‘key-hole’ onto whatever is being clamped secure so that it does not move. This is most important with a job where keeping things straight can be key.

A good pin clamp cylinder can also be made of some specific materials like aluminum and stainless steel. This material is very strong and long lasting so, it can be used to any type of item. As with other types of tools, pin clamp cylinders vary in shape and size as well. This allows them to be tailored for applications on the job. It should be chosen according to the work-load on which this is placed, like for heavy literal larger pin clamp cylinder can help whereas lighter tasks a smaller one suffice.

The first key reasons people use a pin clamp cylinder is the feature it can hold things very tightly and securely. That makes it ideal for heavy-duty jobs Example: for holding a large metal work-piece or to stop things getting out during factory production. Their grip is so tight that ensures a proper fix which is what matters the most when it comes to manufacturing and construction industries.

The first thing that will make you want to use pin clamp cylinders is because of how simple they are. When the pins are pushed in, they lock into location and will not pull out. This feature makes them optimal for any work that requires fast and powerful clamping action. Workers are able to get their job done in a more timely manner because they can put something down and be confident that it will not move or shift. The pin clamp cylinder is one of the most reliable tools in many fields and industries.

Thus to maintain an overall well-functioning pin clamp cylinder, it requires proper care. Regular cleaning and oiling is a must. A cleaning staff is always mounted inside the cylinder, and dirt will get in often times from it so clean up each time. This ensures that it does not attract any dirt or dust which might disrupt its performance. You could also add oil to the moving components in order for the piston moves with higher fluidity. Periodic maintenance helps to keep the pin clamp cylinder compliant and effective with all your clamping demands.

Pin clamp cylinders are likely to grow in power and efficiency as technology advances. In factories and other applications this could make things like exoskeletons more common, enabling factory workers to lift heavy objects as easily as if they were made of balsa wood. Which is to say, pin clamp cylinders will do long and hard services much more efficiently.

Our professional team and business professionals provide complete support and pin clamp cylinder to our customers. It starts with consulting on the product, processing of orders and finishing with after-sales support. Help customers decide on the most appropriate products by utilizing professional knowledge and effective customer relationship management.The company employs a group consisting of design engineers and developers, modern offices, standardized workshops, and cutting-edge production technology. It's a high-tech enterprise that integrates scientific research, development and production. The company is staffed by a team that is highly trained and professional sales engineers and design engineers to provide superior solutions and services to customers.

pin clamp cylinder has a long tradition and vast experience, with world-class technology and the most advanced equipment for production to meet the ever-changing requirements of our customers. At the same time we are dedicated to delivering high-quality goods and services, as well as innovating and conducting research to lead the development of the pneumatic component industry. The company that makes vacuum cups will provide customers with top quality products. The company increases both pre-sales as well as after-sales services to enhance customer satisfaction. We always pursue the goal of "pursuing high-quality, giving first the highest priority to customer service and having excellent technology".

Our products can be customized to meet the demands of each client that is what sets us apart from other companies. The pin clamp cylinder of the product is better, the quality is greater and it is able to meet the needs of clients with greater demands. The product offers a comprehensive and thoughtful after-sales service. For customized products, customers must submit sketches or physical objects and we'll give you a quote that are based on these drawings or actual objects. We can also provide free samples. However, you won't be charged for shipping. After paying the deposit and arranging the customized products and ship the items as soon as it is possible. Typically, the delivery time for customized products is 15-20 days, depending on the quantity.

Suzhou Edith Electric Co., Ltd. It is the main producer of pin clamp cylinder vacuum suction cups, fittings (suction cups seats), fixtures, holding tools, jigs as well as other accessories for automation. Its products are widely used in new energy, tunnels, aviation, steel glass, packaging electronics, automotive and food processing, as well as daily chemical, printing and various other industries. The company follows the business principles of "technology first, pragmatic innovation, customer first, and service first" which is a reflection of the principle of warm service, improving customer satisfaction as a primary direction, and pursuing the best customer service.

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy