Suzhou Edith Electronics Co., Ltd. has a long history and rich experience,with first-class technology and advanced production equipment to meet the constantly changing needs of customers. At the same time,our company is committed to providing high-quality products and services,and continuously promoting research and innovation to lead the development of the pneumatic components industry.

Suzhou Edith Electronics Co., Ltd. mainly produces manipulator vacuum suction cups,fittings (suction cup seats),fixtures,holding tools,jigs and other automation accessories. Its products include FESTO Schmitz of Germany,payobo of Sweden,miaoder of Japan,SMC,Mismi,qiliko of Taiwan,xiaojinjing,Tianxing,Srar,Youxin,etc. its products are widely used in new energy,tunnel,aviation,steel,glass,packaging,automobile,electronics,food,daily chemical,printing and other industries.

Years Company term

Exporting countries

Cooperative enterprises

Million Market size

VACUUM SUCTION CUP

VACUUM SUCTION CUP

Vacuum suction cups are essential tools for lifting and handling various materials using vacuum technology. They are designed to provide strong, reliable suction for applications in automation, packaging, and manufacturing. We mainly produce brands such as Piab, Schmetz, SMC, Fester, Miade and Qilike.Available in various sizes and materials, they ensure safe, efficient, and precise handling of delicate or heavy objects in industrial environments.

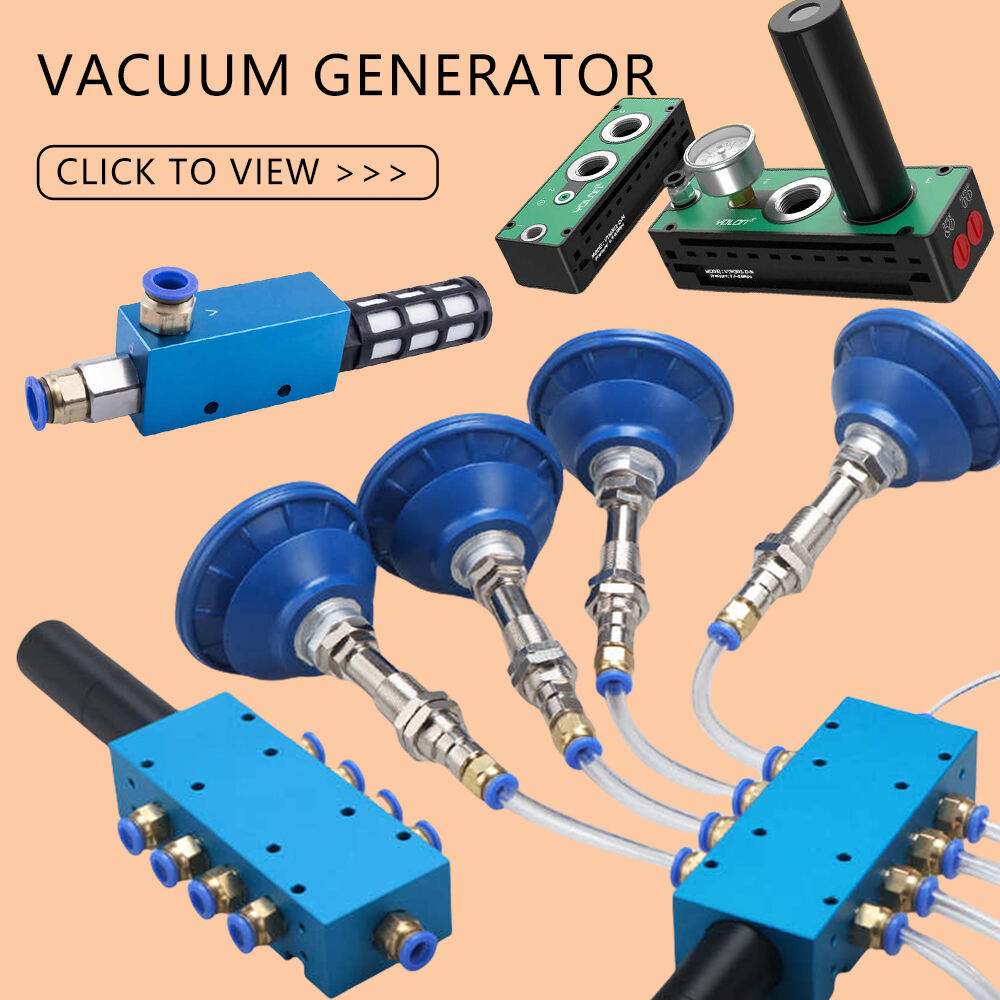

VACUUM GENERATOR

VACUUM GENERATOR

Vacuum generators are devices that create a vacuum for handling, lifting, or moving materials using suction. We offer high-quality vacuum generators from leading brands like Piab, Schmalz, SMC, Festo, and Miflex. These generators provide efficient, reliable vacuum power for applications in automation, robotics, and material handling, ensuring precise and safe operations in various industrial processes.

JIGS AND FIXTURES

JIGS AND FIXTURES

Jigs and fixtures are essential tools in manufacturing, designed to improve efficiency and accuracy. Jigs are used to guide and hold workpieces during operations like drilling or machining, ensuring precise alignment. Fixtures securely hold workpieces in place during production processes, providing stability for consistent and accurate results. Both are widely used across industries such as automotive, aerospace, and electronics to enhance productivity and maintain high-quality standards.

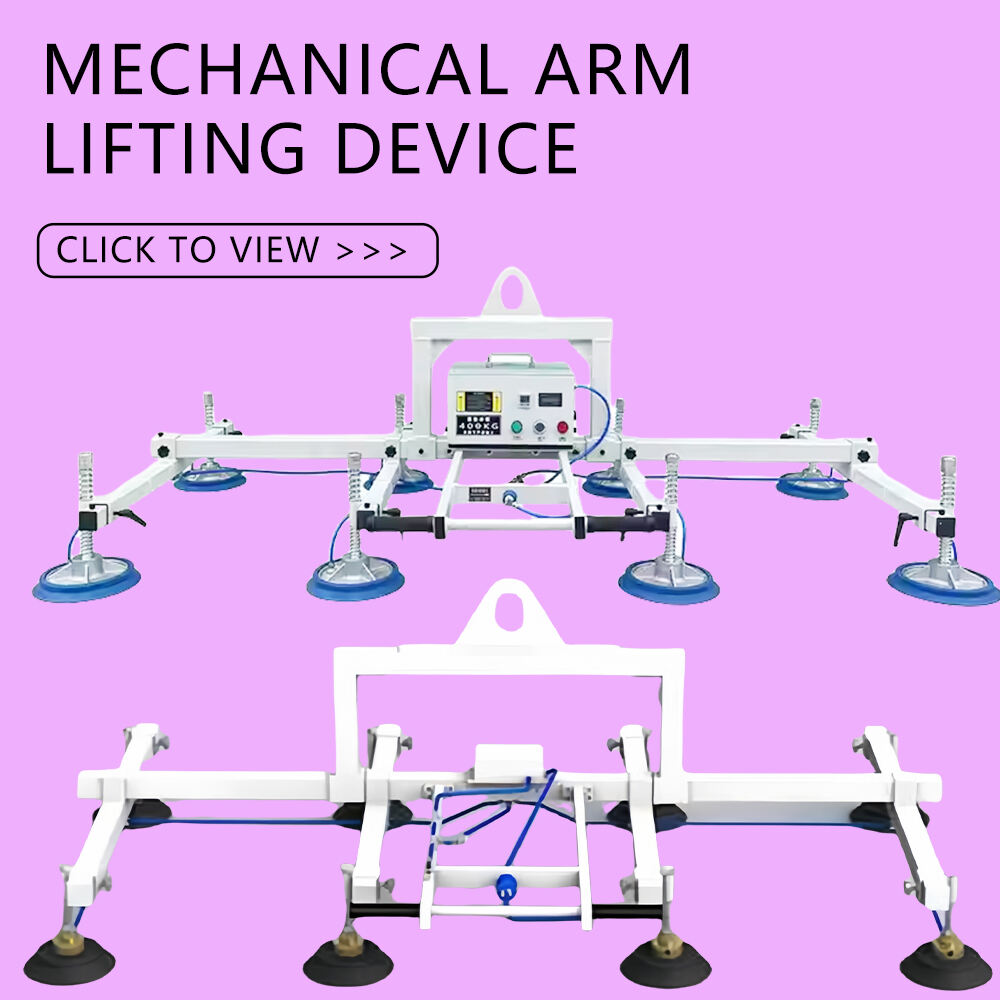

MECHANICAL ARM LIFTING DEVICE

MECHANICAL ARM LIFTING DEVICE

A mechanical arm lifting device is a robotic or mechanical system designed to lift, move, and position heavy or bulky objects in industrial settings. These devices use motors, hydraulic or pneumatic systems to provide precise control and high lifting capacity. Commonly used in manufacturing, assembly lines, and warehouses, they enhance productivity, reduce manual labor, and improve safety by handling heavy loads efficiently and accurately.

PNEUMATIC CYLINDER

PNEUMATIC CYLINDER

Pneumatic cylinder is a mechanical device that uses compressed air to produce linear motion. It consists of a cylinder, piston, and rod, with air pressure acting on the piston to create movement. We offer high-quality pneumatic cylinders from leading brands like SMC, Festo, and Parker. These cylinders are widely used in automation, robotics, and industrial machinery for tasks such as lifting, pushing, or pressing. Known for their reliability, speed, and efficiency, they are ideal for high-speed, repetitive operations across various industries.

PNEUMATIC FIXTURE AND CLAMPING GRIPPER

PNEUMATIC FIXTURE AND CLAMPING GRIPPER

Pneumatic fixture and clamping gripper uses compressed air to hold and manipulate workpieces in automated manufacturing. It provides secure positioning for parts during assembly or machining. These systems offer high speed, precision, and flexibility, improving efficiency in robotic operations, CNC machining, and assembly lines, with common brands like SMC, Festo, and Parker Hannifin.

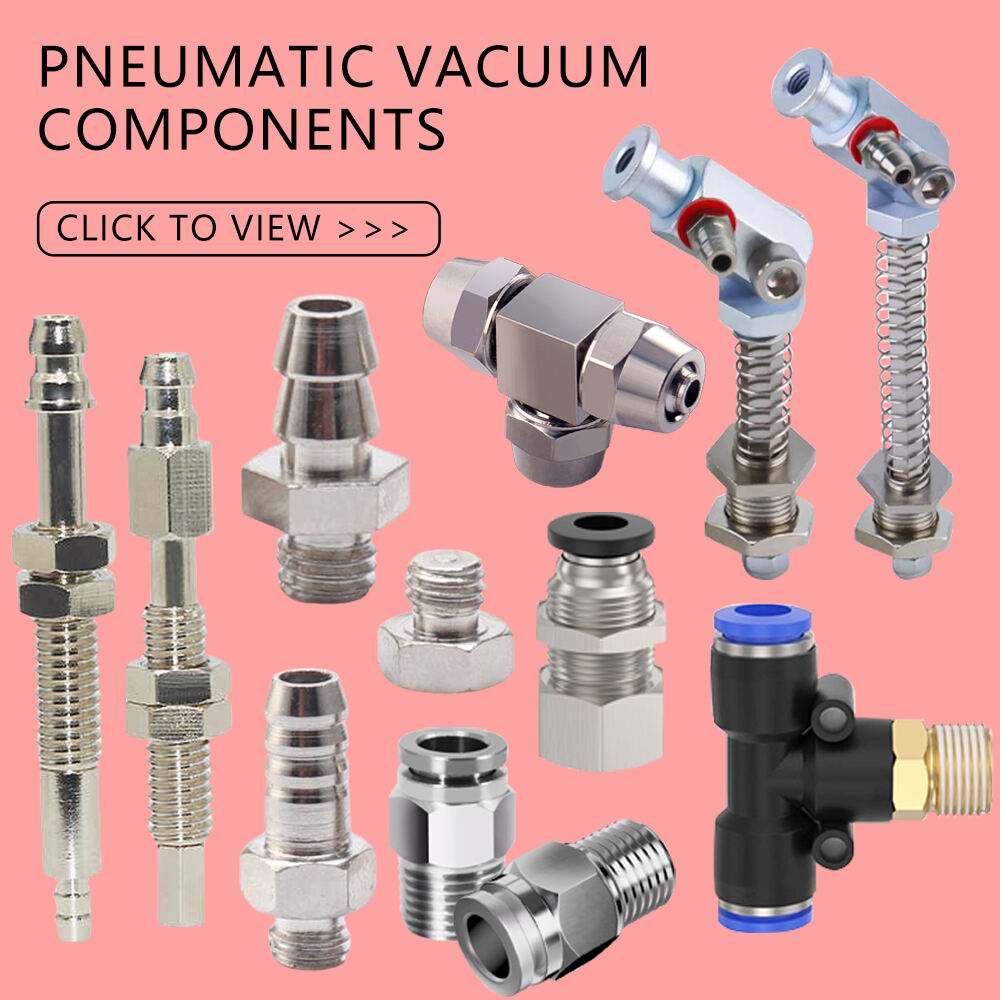

PNEUMATIC VACUUM COMPONENTS

PNEUMATIC VACUUM COMPONENTS

Pneumatic vacuum components include devices like vacuum pumps, generators, grippers, vacuum cups, and pneumatic fittings and hardware (such as couplings, connectors, and valves). These components work together to create and control vacuum pressure for efficient handling, lifting, and transporting of objects in automation, robotics, and material handling applications. Popular brands include Piab, SMC, and Festo.

PNEUMATIC SOLENOID VALVE

PNEUMATIC SOLENOID VALVE

Pneumatic Solenoid Valve controls compressed air flow in pneumatic systems using an electromagnetic solenoid. It is widely used for regulating actuators, cylinders, and other components in automation. Common types include 2/2, 3/2, and 5/2 valves. Popular brands include Festo, SMC, Parker Hannifin, Norgren, and Aventics. These valves offer fast, precise control, making them essential for efficient industrial automation.

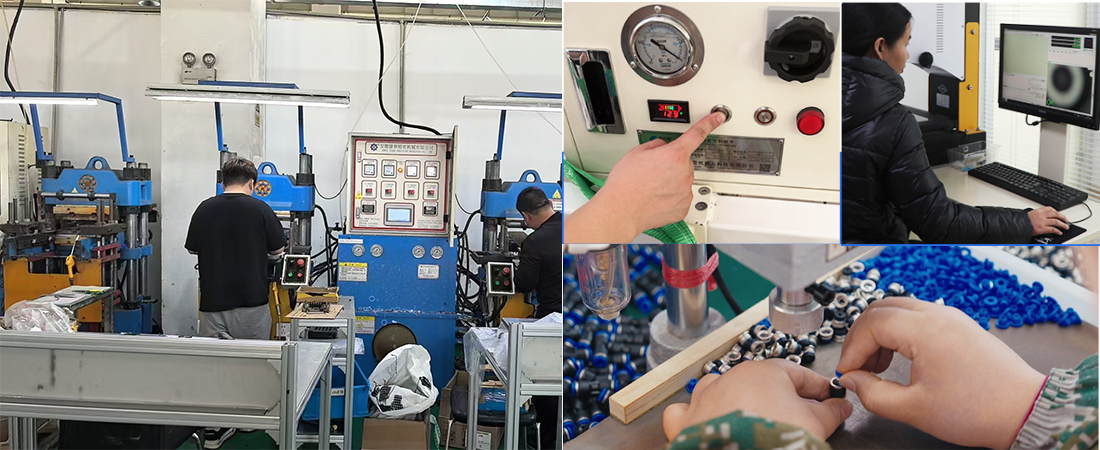

The Company Has Introduced From Korea, Japan And Other Countries More Than 1000 Sets Of International First-class Multi-station ProcessingCenters And CNC Lathes, CNC Milling Machines And A Large Number Of Advanced High-precision Processing Equipment.

Design and drawing by engineers with over 10 years of experience

Multiple CNC machining centers are used for mold processing and customization

The molding production line operates 24 hours a day

Assembly department, assembling the products into shape

Test the adsorption and vacuum effects of the products in the test area

Warehouse staff work in shifts for shipping, ensuring the timeliness of delivery

When you have customized needs for pneumatic vacuum components, you can contact us through various convenient methods. You can call our 24-hour service hotline at +86-18934587277. Our professional customer service team is always ready to answer your questions and record your needs. You can also send an email to [email protected], specifying your specifications, materials, application scenarios, etc. for the product.

Upon receiving your customized requirements, our professional team will immediately conduct a detailed analysis of the demands. Based on factors such as material, size specifications, usage environment, order quantity, and the complexity of the customized process, we will formulate an accurate and transparent quotation plan for you. We promise to meet your cost control requirements to the greatest extent possible while ensuring product quality.

If your customized requirements require the opening of new molds, we have an advanced mold design and manufacturing team that uses professional software for mold design. Meanwhile, we will maintain close communication with you,promptly provide feedback on the details of the mold design and manufacturing process. If necessary, we can make adjustments based on your opinions until the mold meets your requirements.

After completing the mold design (if necessary) or confirming that the existing mold is applicable, we will provide you with samples. After receiving the first draft, you can put forward any revision opinions and suggestions. We will optimize and adjust the plan based on your feedback until you are satisfied with the first draft.

After you provide feedback on the sample and it has been modified and improved by us, we will jointly confirm the final customized plan with you. During the process of confirming the plan, our business and technical teams will communicate with you throughout to ensure that you have a clear understanding of every aspect of the plan. If you have any questions or need further adjustments, we will respond promptly and provide solutions.

Entering the mass production stage, we rely on modern production bases and advanced production equipment, and strictly follow standardized production processes and quality control systems. During the production process, from the procurement of raw materials to the delivery of finished products, every link undergoes strict inspection and monitoring.

Before shipping, we will contact you promptly to inform you of the shipping time, logistics tracking number and other information, so that you can track the transportation status of your goods conveniently. After you receive the goods, if you have any questions, you can contact us at any time. We will handle it for you as soon as possible to ensure your shopping experience is worry-free.

Room 205, Building C, SEG Electronics Market, No. 588 Binhe Road, Huqiu District, Suzhou City, Jiangsu Province

Copyright © Suzhou Edith Electronics Co., Ltd. All Rights Reserved - Privacy Policy